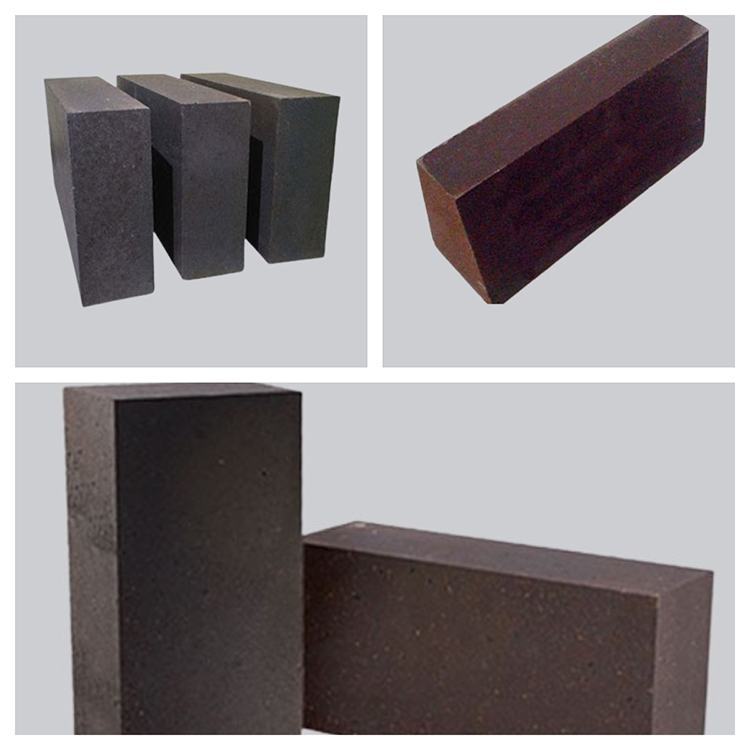

Description of Fused Magnesia Chrome Brick:

Magnesite chrome brick has magnesium oxide (MgO) and chromium oxide (Cr2O3) as the main ingredient, periclase and spinel as main mineral components of refractory products.

1.Common Magnesite chrome brick is made by sintered magnesia and refractory level chrome ore as raw materials. The space between refractory grains is bonded with silicate.

2.Direct-bonded Magnesite chrome brick is made by chrome ore with low content of impurities and pure magnesite,firing at the temperature above 1700°C.

3.Semi-rebonded and Fuse-rebonded magnesite chrome brick are made by fused magnesite chrome sinter.

Fused Semi-Recombined Magnesia Chrome Brick

Semi-recombined magnesia-chrome bricks are dense, low porosity, high temperature strength, better thermal shock resistance than recombined magnesia-chrome bricks, and have strong slag erosion resistance.

Features of Magnesia Chrome Brick

1. Low bulk density, low thermal conductivity, good thermal insulation performance.

2. Refractory category allow direct contact of fire, suitable ofr various atmosphere

3. Good integrity with furnace lining, long service life, easy operation, could be shaped freely

4. Product specification: standard form, normal standard, shaped and special shaped bricks.

5. Can be used in various kilns because of its cheapness and general tray package. Among all of the refractory materials, it is the most widely used.

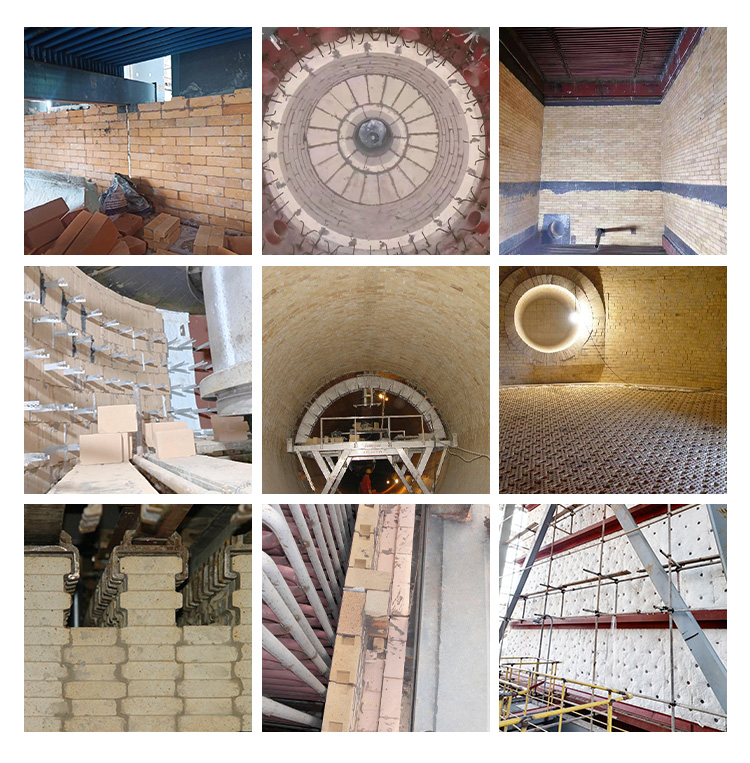

Application of Direct Bond Magnesia-Chrome Bricks

It’s mainly applied to line the sintering zone of the new dry-processing of cement kilns and glass tank furnaces as checkers and the other industrial furnaces.

Fuse-Rebonded Magnesia-Chrome Brick

Main Application:It’s suitable for lining of the slag zone area of refining furnaces of VOD,SKF.

Semi-Rebonded Magnesia-Chrome Brick

Main Application:It’s widely used for every industrial furnaces of the metallurgical and building materials industry.

Physical and chemical indicators:

| Barang | Index | |||

| BMG-26 | BMG-24 | BMG-22 | BMG-20A | |

| MgO % | ≥50 | ≥50 | ≥55 | ≥58 |

| Cr2O3 % | ≥26 | ≥24 | ≥22 | ≥20 |

| SiO2 % | ≤2.0 | ≤2.0 | ≤2.0 | ≤2.0 |

| Porositas yang tampak % | ≤16 | ≤16 | ≤16 | ≤16 |

| Cold Crush Strength MPa | ≥40 | ≥45 | ≥45 | ≥45 |

| 0.2Mpa Refractoriness Under Load℃ | ≥1700 | |||

| Barang | Index | |||

| BMG-18 | BMG-16A | BMG-12A | ||

| MgO % | ≥58 | ≥60 | ≥68 | |

| Cr2O3 % | ≥18 | ≥16 | ≥12 | |

| SiO2 % | ≤2.0 | ≤2.0 | ≤2.0 | |

| Porositas yang tampak % | ≤16 | ≤16 | ≤16 | |

| Cold Crush Strength MPa | ≥40 | ≥45 | ≥45 | |

| 0.2Mpa Refractoriness Under Load℃ | ≥1700 | |||

Fused Recombined Magnesia Chrome Brick

Fused recombined magnesia-chrome brick is a high-grade product with excellent corrosion resistance, and its high temperature performance is between that of fused cast magnesia-chrome brick and sintered magnesia-chrome brick.

Physical and chemical indicators:

| Barang | Index | |||||

| DMG-26 | DMG-24 | DMG-22 | DMG-20 | DMG-16 | DMG-12 | |

| MgO % | ≥50 | ≥50 | ≥55 | ≥58 | ≥62 | ≥68 |

| Cr2O3 % | ≥26 | ≥24 | ≥22 | ≥20 | ≥16 | ≥12 |

| SiO2 % | ≤1.5 | ≤1.5 | ≤1.5 | ≤1.5 | ≤1.5 | ≤1.5 |

| Porositas yang tampak % | ≤16 | ≤16 | ≤16 | ≤16 | ≤16 | ≤16 |

| Cold Crush Strength MPa | ≥40 | ≥40 | ≥40 | ≥40 | ≥40 | ≥40 |

| 0.2Mpa Refractoriness Under Load℃ | ≥1700 | ≥1700 | ≥1700 | ≥1700 | ≥1700 | ≥1700 |

About Rongsheng Refractory Factory

As professional refractory material supplier and manufacturer, Rongsheng Refractory Pabrik is located in Xinmi city, the “Capital of Refractory” in China. We specialize in refractory products for nearly 15 years, covering a full range of shaped and unshaped refractory products, such as High Alumina Series Bricks, Mullite Bricks, Corundum Series Bricks, Silica Series Bricks, Andalusite Bricks, Magnesia Series Brick, Carborundum Brick, Insulating Series Brick, Insulating and Dense Castables, also other related products for more sophisticated applications.

Rongsheng Refractory Factory

Certificates of Rongsheng Refractory Group

Rongsheng Group has a number of international certifications, such as,ISO9001/ISO14001/OHSAS18001/CE/SGS. Besides, Rongsheng Refractory also has a number of domestic certifications.

Professional Sales Team

Engineering Case

Customer Visit

Mengapa memilih kami?

1.Pengalaman Berlimpah. Grup Rongsheng sudah berakhir 20 tahun pengalaman dalam industri refraktori dan kami memiliki pemahaman yang mendalam tentang bahan dan aplikasi yang kami kerjakan. Kami dapat memberikan saran dan panduan ahli untuk membantu pelanggan menemukan solusi terbaik untuk kebutuhan mereka.

2.Produk berkualitas. Kami bangga dapat menyediakan produk refraktori berkualitas tinggi yang tahan lama. Bahan kami bersumber dan diuji dengan hati-hati untuk memastikan mereka memenuhi standar ketat kami.

3.Harga bersaing. Kami menawarkan harga yang kompetitif untuk semua produk kami tanpa mengorbankan kualitas dan menjadikan produk tersebut kompetitif di pasar Anda.

4.Kustomisasi. Kami memahami bahwa setiap pelanggan adalah unik, itulah sebabnya kami menawarkan solusi khusus yang disesuaikan dengan kebutuhan spesifik mereka. Baik itu bentuk atau ukuran custom, kami dapat bekerja dengan pelanggan untuk menciptakan produk yang ideal untuk aplikasi mereka.

5.Keamanan. Kami menganggap serius keselamatan dan memastikan bahwa semua produk kami memenuhi standar keselamatan. Packing aman, waktu pengiriman yang cepat, dan layanan purna jual yang sangat baik.

6.Saham besar. Dengan stok produk yang banyak, kami dapat melayani pelanggan kami dengan lebih baik, hemat, dan mendapatkan keunggulan kompetitif dalam industri mereka.

7. Solusi keseluruhan. Kami menawarkan solusi yang optimal dan komprehensif untuk memasok bahan tahan api yang diperlukan untuk kiln suhu tinggi Anda.

8.Hubungan jangka panjang. Kami percaya dalam membangun hubungan jangka panjang dengan pelanggan kami berdasarkan kepercayaan dan saling menguntungkan. Kami berkomitmen untuk memberikan dukungan dan layanan berkelanjutan untuk memastikan kepuasan pelanggan. Refraktori Rongsheng dapat digunakan di banyak bidang baja, logam nonferrous, kaca, semen, keramik, petrokimia, mesin, ketel, lampu, dan industri tenaga. Apalagi, Distributor industri, kontraktor refraktori, agen penjualan, perusahaan perdagangan, dan konsultan refraktori semua bisa mendapatkan keuntungan dari mempromosikan dan menjual produk refraktori top-of-the-line kami. Dengan fokus pada daya tahan, umur panjang, dan kinerja, produk kami dirancang untuk melebihi harapan Anda dan memberikan hasil terbaik kepada pelanggan Anda.

Jadi memilih kami adalah pilihan yang tepat untuk Anda. Jika Anda tertarik dengan produk kami atau jika Anda memiliki pertanyaan, pls jangan ragu untuk menghubungi kami kapan saja. Kami akan membalas sesegera mungkin.