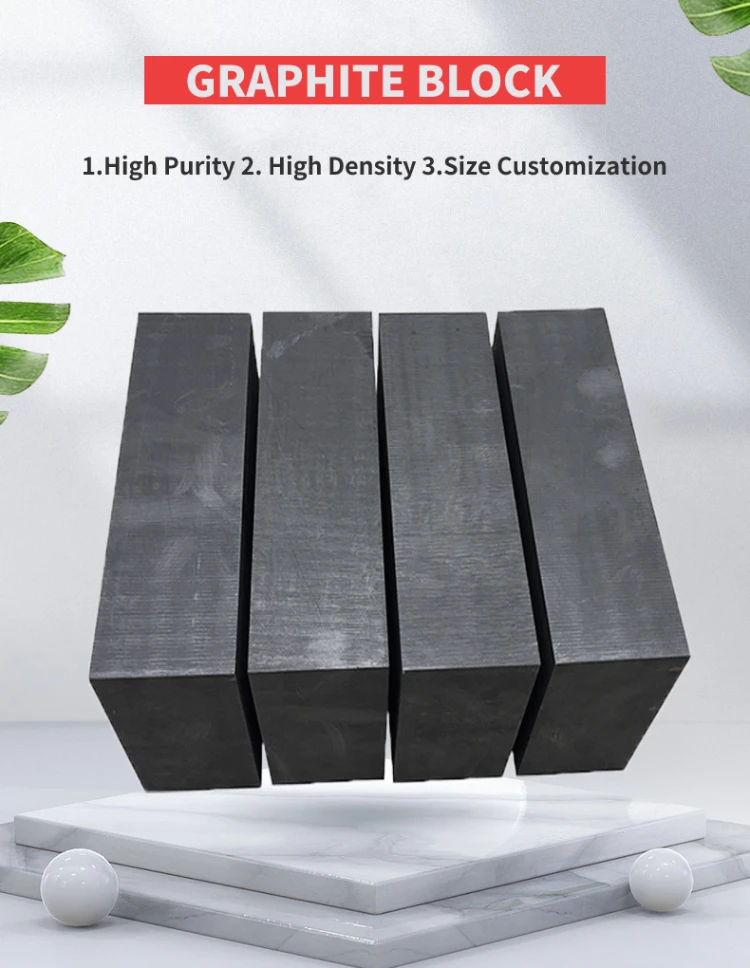

Product Description of Carbon Graphite Blocks For Casting And Foundry

Graphite block is made of domestic petroleum coke, with carbon content above 99%. We have vibrated,molded and isotropic graphite block. They are widely used in such fields as mechanical , electronics, chemical industry and other new industries. We can machine to specific shapes according to customers’ requirements.

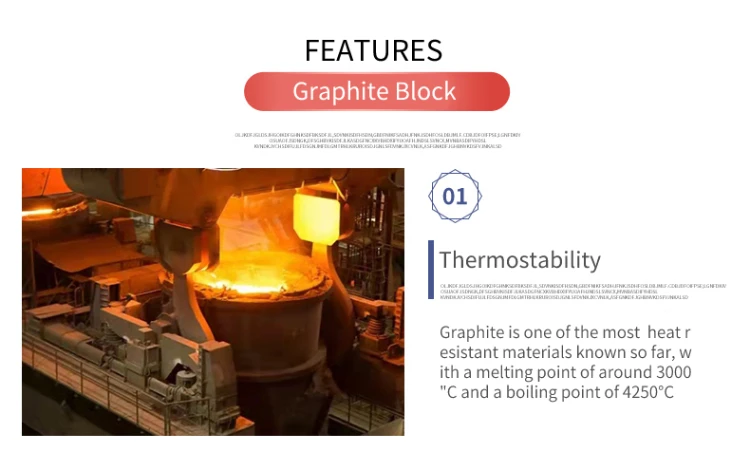

Features of Carbon Graphite Blocks For Casting And Foundry

Graphite block has excellent corrosion resistance, resistance to molten metal erosion and melt erosion, high thermal conductivity, good thermal shock resistance, also has sufficient oxidation resistance and good anti-leakage properties.

Application of Carbon Graphite Blocks For Casting And Foundry

1. Necessary with high temperature resistance in Casting, foundry, metallurgy industries

2. Sintering Application

3. Solar energy industry

4. Graphite Anodes in Electrolysis, chemicals

5. EDM electric discharge machining 6. Glass melting

7. Further machined into small graphite parts

Product Specification of Carbon Graphite Blocks For Casting And Foundry

|

Barang |

Specification |

|||

|

|

SKG-1 |

SKG-2 |

SKG-3 |

|

|

Bulk Density g/cm3 |

≥1.68 |

≥1.63 |

≥1.55 |

|

|

Apparent Porosity % |

≤20 |

≤25 |

≤28 |

|

|

CCS, MPa |

≥28 |

≥25 |

≥18 |

|

|

CMOR, MPa |

≥9 |

≥7 |

≥5 |

|

|

Fixed Carbon % |

≥99.5 |

≥99 |

≥99 |

|

|

Ash % |

≤0.5 |

≤0.5 |

≤0.5 |

|

|

Alkali Resistance |

U/LC |

U/LC |

U/LC |

|

|

Thermal Conductivity W/(m·K) |

Temperature |

≥100 |

≥80 |

≥60 |

|

|

200℃ |

≥80 |

≥60 |

≥40 |

1. Stable product quality, rich production experience

2. Cost saving for customers, professional and technical personnel recommend matching materials according to the working conditions provided by customers

3. Stable product supply

4. After sales service is guaranteed, and there is a special after-sales service team to solve problems for customers

Packaging & Shipping

Customer Visit