Description of Tundish Nozzle For Steel Making

This tundish nozzle is also called zircon/zirconia metering nozzle, tundish metering nozzle. Tundish Nozzles are an integral part of Continuous Steel Casting process. As a professional Tundish Nozzles Manufacturer and Wholesale Tundish Nozzles Supplier, Rongsheng Refractory Factory manufacturers a very wide range of Tundish Nozzles used for controlling the flow of steel from the Tundish to the Continuous Casting equipment.

We provide a very wide range of Tundish Nozzles used for controlling the flow of steel from the Tundish to the Continuous Casting equipment including:

*Zirconia/ Zircon Nozzles – Manufactured in 65% to 95% Zirconia.

*Isostatically Pressed Nozzles – made in Alumina Carbon quality for medium and small steel plants.

Refractory zirconia tundish nozzle is made of zirconia and inported baddeleyite, formed by high tension and baked in high temperature when stablized by special technology. Different size and types of refractory zirconia tundish nozzles are designed and made according to user’s different steel-making conditions and requirements.

Features of Tundish Nozzle Material

Rongsheng tundish nozzle use stable zirconia and high quality zircon by a special process stability, from high pressure molding, high temperature firing. According to the user’s different steel-making environment and the use requirements to set the nozzle specifications.

1.Long casting sequence time

2.Controlled casting speed

3.Excellent resistance to oxidation

4.Prevent clogging to improve productivity

5.Special compositions of nozzles as per use in the industry

Application of Refractory Manufacturer Tundish Zirconia Nozzle

Currently, our products have been used in many carbon burning furnaces, CFB boilers in power plant, cement rotary kilns,

non-ferrous metal melting furnaces, blast furnaces, hot-blast furnaces, coking furnaces, steel ladles, glass melting kilns and other high temperature industries all over the world.

In casting steel, refractory zirconia tundish nozzle is mainly used in successive-casting intermediary small square adobes, big square adobes, rectangle adobes and small board adobes.

Product Specification of Refractory Tundish Nozzle :

1.Tundish Nozzle

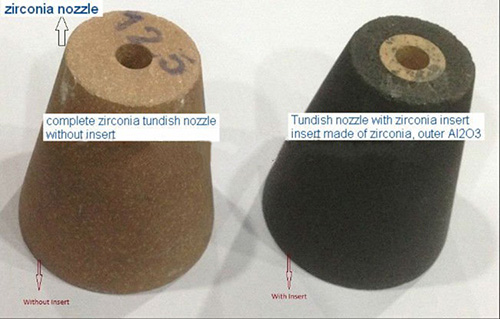

This type is compsite material. outter nozzlei s alumina and inner nozzle is zirconia insert Advantage: the most cost-effective production process.

| Chemical and Physical Properties | RSTN-AIC75 | RSTN-AIC80 | RSTN-AI75 | RSTN-Zr96RS | RSTN-Zr65 |

| Al2O3 ≥ % | 75 | 80 | 94 | -85 | – |

| ZrO2≥% | – | – | (Insert) 92-96 | 65 | |

| C≥% | 4 | 4 | – | – | – |

| Apparent porosity ≤ | 8 | 7 | 15 | 9 | 20 |

| Bulk density g/m3≥ | 2.90 | 2.95 | 2.95 | 3.05 | 3.5 |

| Compressive strength (MPa)≥ | 60 | 60 | 120 | 80 | – |

| High temperature bending strength (MPa) (1400*0.5h) MPa;z | 6 | 7 | 15 | 20 | – |

2.Zirconia insert–intergral material only zirocnia material.

| Chemical and Physical Properties | RSZR60 | RSZR70 | RSZR80 | RSZR85 | RSZR95 |

| ZrO2 ≥ % | 60 | 70 | 80 | 90 | 95 |

| Apparent porosity≤ | 21 | 20 | 18 | 15 | 6 |

| Bulk density g/m3 ≥ | 3.70 | 3.90 | 4.0 | 4.35 | 5.2 |

| Refractories≥℃ | 1800 | 1800 | 1850 | 1900 | 1900 |

Packing&Shipping

1- International standard seaworthy exportable packing.

2- Wooden pallet.

3- Wooden / bamboo case (box).

4- Further packing information will be based on customer’s requirements.

Our Sevices For All Customers

1.Pre-Sales Consulatation

We are not only provide products,but also the use and the design of products in the kiln.We salesman are all professional experts who can give you proposals,make your energy-saving more simple.

2.Sample Service

We can provide free sample for your testing before placing orders.

3.Packing

We have our own sea-worthy packing which can meet needs for mostof our clients.However,if you have spcific packing requiments, please send you reqiuments to us ,we can use your packing.

4.Delivery

We will provide surpervision on each batch of goods with report and photos.Proper logsitic method is available for different kind of products.

5.After-Sales Service

We will follow-up your response after the shipmens. If there is a complaint, we will give a proper settlement in 2 working days!