Description of Beryllium Oxide Ceramics:

Beryllium oxide belongs to cubic crystal system, with a density of 3.03g/cm3 and a melting point of 2570 ℃. It has high thermal conductivity and thermal conductivity λ It is 200-250W/(m · K), and has good thermal shock resistance. The dielectric constant is 6-7 (0.1MHz), and the dielectric loss tangent is about 4 × 10-4 (0.1GHz), can be used for a long time under 1800 ℃ vacuum, 2000 ℃ inert atmosphere and 1800 ℃ oxidation atmosphere.

Beryllium oxide ceramic is an advanced ceramic with beryllium oxide (BeO) as the main component. It is characterized by high thermal conductivity, high melting point, high strength, high insulation, high chemical and thermal stability, low dielectric constant, low dielectric loss and good process adaptability. It is a structural ceramic material with excellent performance and is widely used in special metallurgy, aerospace, vacuum electronics, nuclear technology, microelectronics and optoelectronics, Especially in high-power semiconductor devices, high-power integrated circuits, high-power microwave vacuum devices and nuclear reactors, it has been the mainstream ceramic materials for preparing high thermal conductivity components.

Typical applications:

Due to its excellent thermal, electrical, nuclear and mechanical properties, beryllium oxide ceramics can be used as carrier parts and assemblies in the aerospace field, as a neutron retarder and radiation protection material in atomic reactors in the nuclear industry, as a high-performance, high-power microwave package, as well as a wide band high-power electric vacuum device, and as a crucible for melting rare metals and precious metals, such as uranium and plutonium, It can also be used as refractory material for supporting rods of heating elements, etc., and has an excellent application in various fields.

Technical Parameter of Beryllium Oxide Ceramics:

Performance index

| Item | Test Condition | Unit | Index |

| Bulk Density | g/cm3 | ≥2.85 | |

| Beryllium oxide content | % | ≥99 | |

| Air tightness | Pass | ||

| Liquid permeability | Pass | ||

| Flexural strength | MPa | ≥170 | |

| Thermal shock resistance | Pass | ||

| Coefficient of linear expansion | 20℃-500℃ | ×10-6 /℃ | 7-8.5 |

| Thermal conductivity | 25℃ | W/(m·k) | ≥250 |

| Partial constant | 100℃ | W/(m·k) | ≥190 |

| Tangent value of dielectric loss angle | 1MHz 20℃ | 6.5-7.5 | |

| Volume resistivity | 10GHz 20℃ | 6.5-7.5 | |

| Breakdown strength | 1MHz 20℃ | ×10-4 | ≤4 |

| Chemical stability | 10GHz 20℃ | ×10-4 | ≤8 |

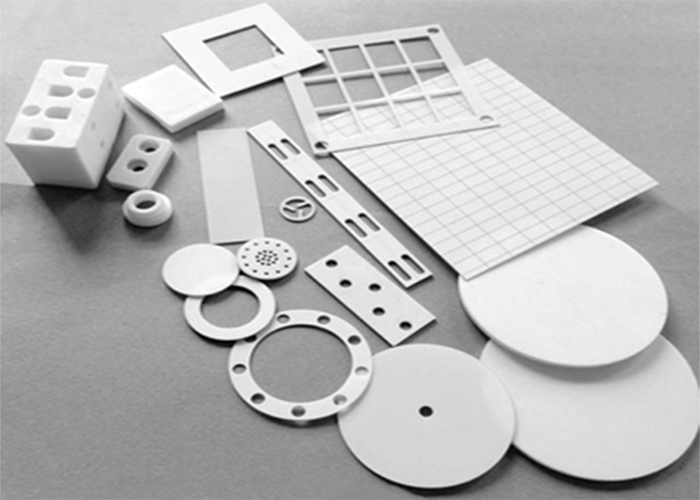

Main Products:

| N o | Product | Application |

| 1 | 99 Beryllium oxide ceramic substrate | Solid state electronics, various high-power devices, optical communication |

| 2 | 99 Beryllium oxide ceramic metallized substrate | Solid state electronics, various high-power devices, optical communication |

| 3 | 99 Beryllium oxide ceramic polishing substrate | Solid state electronics, various high-power devices, optical communication |

| 4 | 97 Beryllium oxide ceramic substrate | Solid state electronics, various high-power devices, optical communication |

| 5 | 99 Beryllium oxide ceramic pole | High power traveling wave tube |

| 6 | 99 Beryllium oxide ceramic tile | High power traveling wave tube |

| 7 | 99 Beryllium oxide ceramic column | High power electronic device |

| 8 | 99 Beryllium oxide ceramic cylinder | Vacuum device |

| 9 | 99 Beryllium oxide ceramic crucible | Melting |

| 10 | 99.5 Beryllium oxide ceramic shaped parts | Nuclear, high power period, vacuum device, microwave |

Why choose us?

1.Abundant Experience. Rongsheng Group have over 20 years experience in the refractory industry and we have a deep understanding of the materials and applications we work with. We can provide expert advice and guidance to help customers find the best solutions for their needs.

2.Quality products. We pride ourselves on providing high-quality refractory products that are made to last. Our materials are carefully sourced and tested to ensure they meet our strict standards.

3.Competitive Price. We offer competitive pricie on all of our products without sacrificing quality and make the products competitive in your market.

4.Customization. We understand that every customer is unique, which is why we offer customized solutions tailored to their specific requirements. Whether it’s a custom shape or size, we can work with customers to create the ideal product for their application.

5.Safety. We take safety seriously and ensure that all of our products meet safety standards. Safty packing, prompt delivery time, and excellent after-sales services.

6.Large stocks. With a large stock of products on hand, we can better serve our customers, save money, and gain a competitive edge in their industry.

7. Overall solutions. We offer optimal and comprehensive solutions to supply the necessary refractory material for your high temperature kiln.

8.Long-term relationships. We believe in building long-term relationships with our customers based on trust and mutual benefit. We are committed to providing ongoing support and service to ensure customer satisfaction. Rongsheng Refractory can be used in many fields of steel, nonferrous metals, glass, cement, ceramic, petrochemical, machinery, boiler, light, and power industries. What’s more, Industrial distributors, refractory contractors, sales agents, trading companies, and refractory consultants can all benefit from promoting and selling our top-of-the-line refractory products. With a focus on durability, longevity, and performance, our products are designed to exceed your expectations and provide your customers with the best possible results.

So choosing us is the right choice for you.If you are interested in our products or if you have any question, pls feel free to contact us at any time. We will reply as soon as possible.