Description of Continuous Casting Refractories Submerged Entry Nozzle SEN:

The submerged nozzle is a pouring refractory casing installed at the bottom of the intermediate tank in continuous steel casting equipment and inserted below the liquid level of the mold steel. The main function of the immersed nozzle is to prevent secondary oxidation of the intermediate tank injection flow and splashing of molten steel.

The main function of the submerged nozzle is to prevent secondary oxidation of the tundish tank injection flow and splashing of molten steel; to prevent the mold slag from being involved in the molten steel; and to improve the flow state and heat flow distribution of the injection flow in the crystallizer. This promotes the uniform growth of the billet shell in the crystallizer, which is beneficial to the elimination of gas and inclusions in the steel.

Submerged Nozzle can protect the molten steel from oxidation when it flows into the crystallizer from the tundish, evenly distribute the molten steel into the crystallizer and control the flow state of the molten steel in the crystallizer, with good slag resistance, anti blocking, long service life and low accident rate.

Performance Characteristics of Our Submerged Nozzle Continuous Casting Refractories

Our submerged entry nozzle has the following characteristics:

1.Good sealing: It has a good fit with our plug products, and the sealing performance is good after the stopper and the nozzle are

closed.

2.Anti-erosion: Advanced material formulation to effectively resist the physicochemical effects of the melt.

3.Antioxidant: Advanced anti-oxidation mechanism to ensure good protection of graphite in products.

4.High temperature resistance:1770 °C5.High strength: high-quality materials, high-pressure pressing, reasonable combination, high temperature strength, scientific

product design, high anti-scour ability.

6.Long service life: ductile iron casting life is generally not less than 48 hours, gray iron casting is generally not less than

72 hours.

Technical Parameter of Submerged Nozzle Continuous Casting Refractories:

| Artículo | Índice | |||

| JSK55 | JSK50 | JSK45 | JSK40 | |

| Al2O3 % | ≥55 | ≥50 | ≥45 | ≥40 |

| C % | ≥16 | ≥18 | ≥20 | ≥22 |

| Flexural Strength MPa | ≥5.5 | ≥5.5 | ≥5.5 | ≥5 |

| porosidad aparente % | ≤19 | ≤19 | ≤19 | ≤19 |

| Densidad aparente g/cm3 | ≥2.36 | ≥2.32 | ≥2.28 | ≥2.18 |

Slag Area:

| Artículo | Índice | |||

| Z75 | Z70 | Z65 | Z55 | |

| ZrO2 % | ≥75 | ≥70 | ≥65 | ≥55 |

| C % | ≥9 | ≥12 | ≥15 | ≥18 |

| porosidad aparente % | ≤21 | ≤21 | ≤21 | ≤22 |

| Densidad aparente g/cm3 | ≥3.6 | ≥3.5 | ≥3.4 | ≥3.2 |

Packing&Shipping

About Rongsheng Refractory

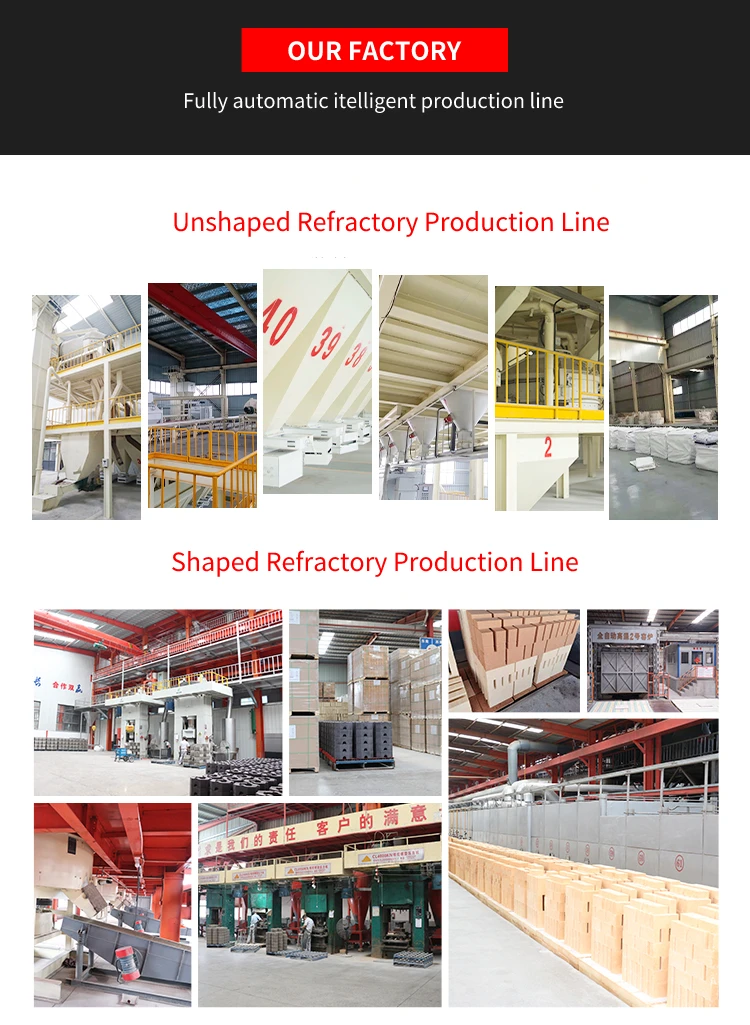

As professional refractory material supplier and manufacturer, Rongsheng Refractory Fábrica is located in Xinmi city, the “Capital of Refractory” in China. We specialize in refractory products for nearly 20 years, covering a full range of shaped and unshaped refractory products, such as High Alumina Series Bricks, Mullite Bricks, Corundum Series Bricks, Silica Series Bricks, Andalusite Bricks, Magnesia Series Brick, Carborundum Brick, Insulating Series Brick, Insulating and Dense Castables, also other related products for more sophisticated applications. We are recognized as a top fire brick factory and refractory material supplier.

Certificates of Rongsheng Refractory Group

Rongsheng Group holds several international certifications, including ISO9001, ISO14001, OHSAS18001, CE, and SGS. We also have numerous domestic certifications. As a top refractory company and refractory suppliers, we are dedicated to innovation and customer satisfaction. We collaborate with universities to establish research and development centers, providing customers with differentiated, serialized, and customized refractory products and services.

Professional Sales Team

Customer Visit

Join our satisfied customers from over 100 countries and regions who trust Rongsheng Refractory for their needs. As a leading refractory brick manufacturers and refractory material supplier, we are here for you at any time. Welcome your inquiry.

Por qué elegirnos?

1.Experiencia abundante. Rongsheng Group tiene más 20 años de experiencia en la industria refractaria y tenemos un profundo conocimiento de los materiales y aplicaciones con los que trabajamos. Podemos proporcionar asesoramiento y orientación de expertos para ayudar a los clientes a encontrar las mejores soluciones para sus necesidades..

2.Productos de calidad. Nos enorgullecemos de ofrecer productos refractarios de alta calidad hechos para durar.. Nuestros materiales se obtienen y prueban cuidadosamente para garantizar que cumplan con nuestros estrictos estándares..

3.Precio competitivo. Ofrecemos precios competitivos en todos nuestros productos sin sacrificar la calidad y hacemos que los productos sean competitivos en su mercado..

4.personalización. Entendemos que cada cliente es único., por eso ofrecemos soluciones personalizadas adaptadas a sus requisitos específicos. Ya sea una forma o tamaño personalizado, podemos trabajar con los clientes para crear el producto ideal para su aplicación.

5.Seguridad. Nos tomamos la seguridad en serio y nos aseguramos de que todos nuestros productos cumplan con los estándares de seguridad.. Embalaje de seguridad, tiempo de entrega rápido, y excelentes servicios post-venta.

6.Grandes existencias. Con un gran stock de productos a la mano, podemos servir mejor a nuestros clientes, ahorrar dinero, y obtener una ventaja competitiva en su industria.

7. Soluciones generales. Ofrecemos soluciones óptimas e integrales para suministrar el material refractario necesario para su horno de alta temperatura.

8.Relaciones a largo plazo. Creemos en construir relaciones a largo plazo con nuestros clientes basadas en la confianza y el beneficio mutuo.. Estamos comprometidos a brindar soporte y servicio continuos para garantizar la satisfacción del cliente.. El refractario Rongsheng se puede utilizar en muchos campos del acero, metales no ferrosos, vaso, cemento, cerámico, petroquímico, maquinaria, caldera, luz, y las industrias de energía. Y lo que es más, distribuidores industriales, contratistas refractarios, agentes de ventas, companías comerciales, y los consultores refractarios pueden beneficiarse de la promoción y venta de nuestros productos refractarios de primera línea.. Con un enfoque en la durabilidad, longevidad, y rendimiento, nuestros productos están diseñados para superar sus expectativas y brindar a sus clientes los mejores resultados posibles.

Por lo tanto, elegirnos es la opción correcta para usted. Si está interesado en nuestros productos o si tiene alguna pregunta., por favor no dude en contactarnos en cualquier momento. Le contestaremos lo antes posible.