Description of AZS33# AZS36# AZS41# Fire Brick Fused Cast AZS Zirconia Corundum Refractory Bricks

AZS Brick is a kind of fused cast zirconia-corundum refractory brick which is short writing of abbreviation that AZS from “A” of Al2O3, “Z” of ZrO2 and “S” of SiO2. According to the difference of Al2O3 contents, the AZS bricks usually are classified into the AZS33, AZS36 and AZS41 for your Selection. Such as No. 33 fused cast zirconia-corundum refractory brick adopts the “AZS-33#” as its abbreviation, No. 36 fused cast zirconia-corundum refractory brick adopts the “AZS-36#” as its abbreviation and No. 41 fused cast zirconia-corundum refractory brick adopts the “AZS-41#” as its abbreviation.

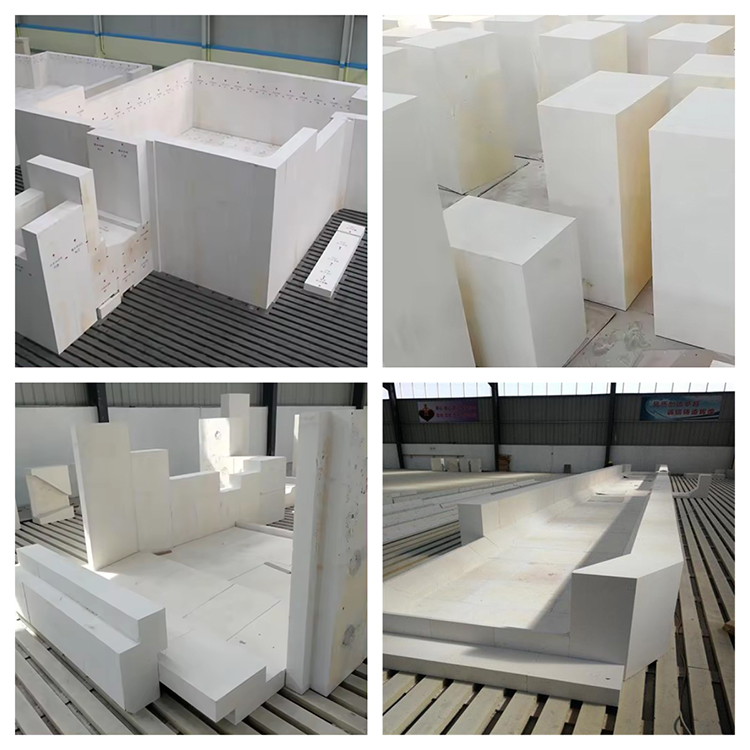

Rongsheng Refractory Bricks Manufacturer in China also as professional AZS Zircon Corundum Brick Manufacturer, has professional manufacturing and exporting experience for more than 20 years , which will be your best choice to buy high quality AZS refractory bricks at lower price. You can contact us to visit our refractory manufacturing factory when you are convenient. You are also welcomed to contact us for more information and we will offer you the best price quotation right now.

Product Features of AZS33# AZS36# AZS41# Fire Brick Fused Cast AZS Zirconia Corundum Refractory Bricks

1. High refractoriness and high refractoriness under load.

2. Good wear-resistance, slag-resistance and alkali corrosion resistance.

3. Good thermal stability.

4. High compression strength.

5. Long service life.

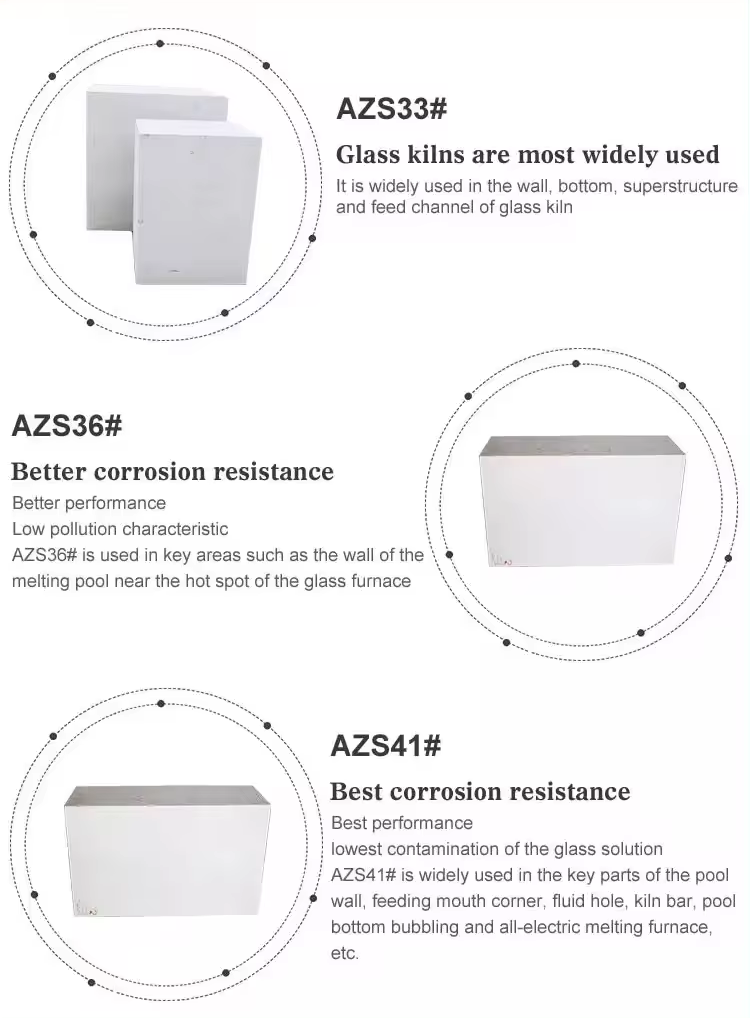

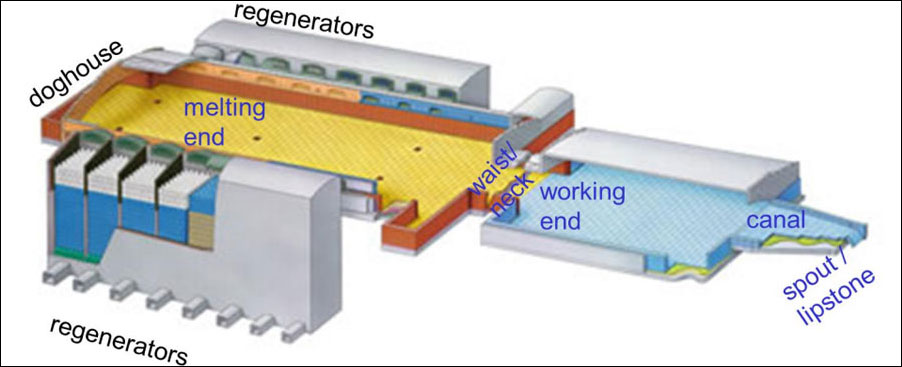

Zirconium Corundum bricks fused by oxidation method have good corrosion resistance to glass liquid and low stone rate 、bubble and glass phase exudation rate ,do not pollute the glass liquid. It is mainly used in the contact parts of the glass kiln and the glass liquid, and the parts with high corrosion resistance requirements, which are selected according to the use parts.

Product Application of AZS33# AZS36# AZS41# Fire Brick Fused Cast AZS Zirconia Corundum Refractory Bricks

Fused Cast AZS33 Brick is widely used for glass furnace for superstructure, working pool side wall, paving blocks, feeder channels, tank bottom, C-shaped block and doghouse crown,etc.. Fused Cast AZS36 Brick is mainly used for sidewall, doghouses, throat, bottom budding, Dam blocks, electric block corners. Fused Cast AZS41 Brick is mainly used for sidewalls, doghouses, bottom budding, Dam blocks, electric block corners.

Technical Requirements For Melting

(1) Using the long arc melting process and the secondary voltage is controlled between 320-380. Using high-voltage melting in the initial stage of melting, 380V for secondary voltage , controlling 320V as secondary voltage during the refining, the arc length must reach 50-60mm.

(2) Current selection: At the initial stage of melting, keeping the current between 3500-4000 Ann, and pay attention to the three-phase electrode current Situation at any time, try to maintain the balance, If using strong current for refining, the current control at 4500 Ann.

(3) Oxygen blowing: oxygen is injected step by step, oxygen is blown twice per furnace and the pressure keep 1.4-1.6 megapascals, when the oxygen is blown oxygen lance should be inserted into 1/2 of material liquid depth, and shake slowly to make Oxidation more sufficient.

(4) Melting time: Melting time for per furnace is about 150 minutes, 120 minutes for melting and 30 minutes for refining.

(5) Casting temperature is 1850-1950°C, winter must be above 1950°C.

Parameter of AZS33# AZS36# AZS41# Fire Brick Fused Cast AZS Zirconia Corundum Refractory Bricks

| Artículo | Índice | |||

| AZS33# | AZS36# | AZS41# | ||

| Al2O3 % | Balance | |||

| ZrO2 % | 32 | 34 | 40 | |

| SiO2 % | 16 | 14 | 12.5 | |

| Fe2O3+TiO2+CaO+MgO+K2O+Na2O % | ≤2.5 | ≤2.5 | ≤2.0 | |

| Densidad a Granel (Dense part) gramos/cm3 | 3.7 | 3.75 | 4.0 | |

| Apparent Porosity % | 2.0 | 1.5 | 1.3 | |

| Glass Phase Initial Precipitation Temperature ℃ | 1400 | 1400 | 1400 | |

| Glass Phase Exudation % 1500℃×4h | 2.0 | 3.0 | 3.0 | |

| Static Resistance To Liquid Glass Erosion Depth mm/24h

Ordinary Soda Lime Glass 1500℃×36h |

1.6 | 1.5 | 1.3 | |

| Bubble Precipitation Rate %

Ordinary Soda Lime Glass 1300℃×36h |

2.0 | 1.5 | 1.0 | |

| Specific Gravity g/cm3 | PT/QX | 3.5 | 3.5 | 3.6 |

| ZWS | 3.6 | 3.6 | 3.8 | |

| WS | 3.65 | 3.7 | 3.9 | |

About Rongsheng Refractory Factory

As professional refractory material supplier and manufacturer, Rongsheng Refractory Fábrica is located in Xinmi city, the “Capital of Refractory” in China. We specialize in refractory products for more than 20 years, covering a full range of shaped and unshaped refractory products, such as High Alumina Series Bricks, Mullite Bricks, Corundum Series Bricks, Silica Series Bricks, Andalusite Bricks, Magnesia Series Brick, Carborundum Brick, Insulating Series Brick, Insulating and Dense Castables, also other related products for more sophisticated applications.

Certificates of Rongsheng Refractory Group

Rongsheng Refractory Group has a number of international certifications, such as,ISO9001/ISO14001/OHSAS18001/CE/SGS. Besides, Rongsheng Refractory also has a number of domestic certifications.

Professional Sales Team

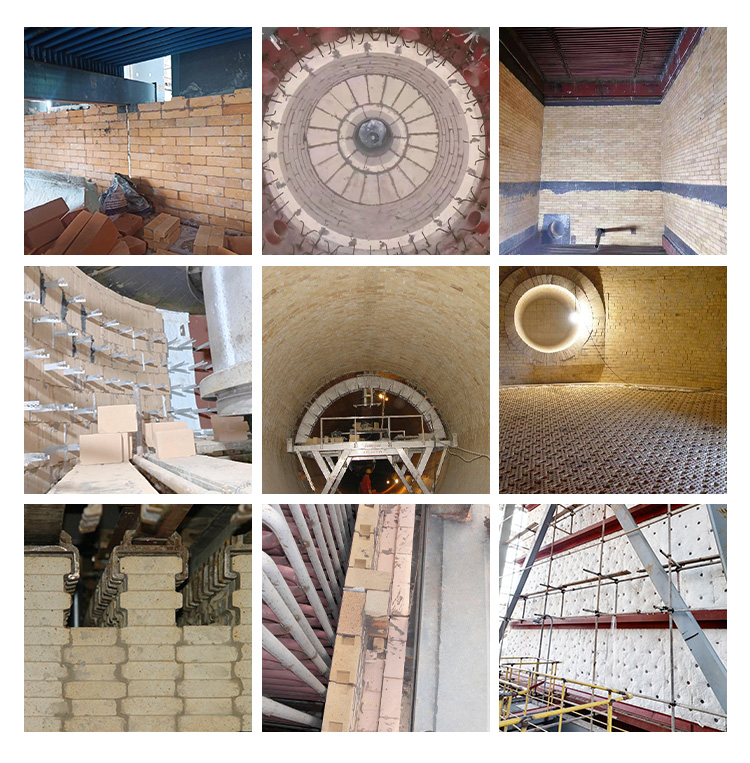

Engineering Case

Customer Visit

Por qué elegirnos?

1.Experiencia abundante. Rongsheng Group tiene más 20 años de experiencia en la industria refractaria y tenemos un profundo conocimiento de los materiales y aplicaciones con los que trabajamos. Podemos proporcionar asesoramiento y orientación de expertos para ayudar a los clientes a encontrar las mejores soluciones para sus necesidades..

2.Productos de calidad. Nos enorgullecemos de ofrecer productos refractarios de alta calidad hechos para durar.. Nuestros materiales se obtienen y prueban cuidadosamente para garantizar que cumplan con nuestros estrictos estándares..

3.Precio competitivo. Ofrecemos precios competitivos en todos nuestros productos sin sacrificar la calidad y hacemos que los productos sean competitivos en su mercado..

4.personalización. Entendemos que cada cliente es único., por eso ofrecemos soluciones personalizadas adaptadas a sus requisitos específicos. Ya sea una forma o tamaño personalizado, podemos trabajar con los clientes para crear el producto ideal para su aplicación.

5.Seguridad. Nos tomamos la seguridad en serio y nos aseguramos de que todos nuestros productos cumplan con los estándares de seguridad.. Embalaje de seguridad, tiempo de entrega rápido, y excelentes servicios post-venta.

6.Grandes existencias. Con un gran stock de productos a la mano, podemos servir mejor a nuestros clientes, ahorrar dinero, y obtener una ventaja competitiva en su industria.

7. Soluciones generales. Ofrecemos soluciones óptimas e integrales para suministrar el material refractario necesario para su horno de alta temperatura.

8.Relaciones a largo plazo. Creemos en construir relaciones a largo plazo con nuestros clientes basadas en la confianza y el beneficio mutuo.. Estamos comprometidos a brindar soporte y servicio continuos para garantizar la satisfacción del cliente.. El refractario Rongsheng se puede utilizar en muchos campos del acero, metales no ferrosos, vaso, cemento, cerámico, petroquímico, maquinaria, caldera, luz, y las industrias de energía. Y lo que es más, distribuidores industriales, contratistas refractarios, agentes de ventas, companías comerciales, y los consultores refractarios pueden beneficiarse de la promoción y venta de nuestros productos refractarios de primera línea.. Con un enfoque en la durabilidad, longevidad, y rendimiento, nuestros productos están diseñados para superar sus expectativas y brindar a sus clientes los mejores resultados posibles.

Por lo tanto, elegirnos es la opción correcta para usted. Si está interesado en nuestros productos o si tiene alguna pregunta., por favor no dude en contactarnos en cualquier momento. Le contestaremos lo antes posible.