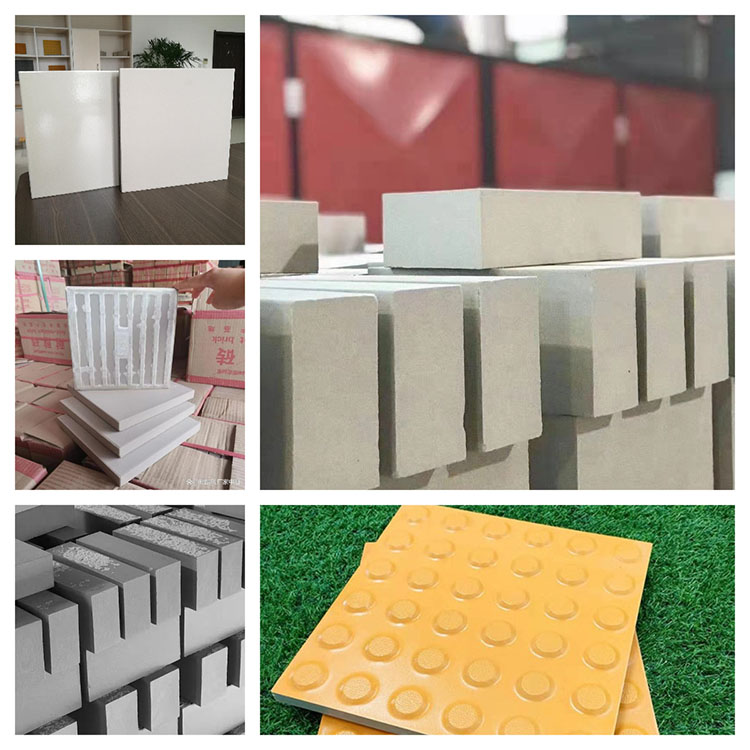

Description of Good Price Acid Resistant Brick Hot Sale Acid Resistant Tile

The acid-resistant brick, acid resistant tile or acid resistant ceramic tiles has the characteristics of high acidity resistance, low water absorption, not easy to oxidize at room temperature and not easy to be polluted by medium. Except hydrofluoric acid and hot phosphoric acid, it has excellent corrosion resistance to wet chlorine, brine, hydrochloric acid, sulfuric acid, nitric acid and alkali of any concentration at room temperature.

Product Features of Acid Resistant Brick And Acid Resistant Ceramic Tiles

1. Good acid resistant.

2. High strength and Wear resistance.

3. Low water absorption and low apparent porosity.

4. Good eroding proofing and impact resistance.

5. High temperature resistant.

6.Good thermal shock resistance.

7. High mechanical strength.

Acid Resistant Bricks/Acid Proof Tiles Solutions

Rongsheng Refractory Group focused on refractory manufacturing for more than 20 years. We mainly supply refractory bricks, insulation bricks, castables, refractory cement and other high-temperature furnace refractories. We can also offer proven solutions to fight corrosion from Acids/Alkalis, Chemicals and Highly Corrosive Environments.

We provide Acid Resistant Solutions for Chemical Storage/Reaction Tanks, Drains, Battery Rooms, Floors, ETP, Galvanizing Tanks, Pickling Areas, Demineralization Plants, Towers, Chests, Digestors, Drying Towers, Neutralization pits etc.

We have served numerous customers by saving their equipments & structures from continuous chemical attack and extended the life of tanks, vessels, reactors & structures hence saving huge capital expenditure cost & reducing production down-time.

Product & Service We offer

Acid Resistant Brick & Tile Lining

Chemical/Corrosion Resistant Coatings

Corrosion Audits

Design Engineering Consultancy

Estimation & Product Selection

Complete Installation & Supervision

Maintenance Solutions

Products used in conjunction with:

Epoxy resin cement

Phenolic resin cement

Furan resin cement

Product Application of Rongsheng Good Price Acid Resistant Brick Hot Sale Acid Resistant Tile

Rongsheng Acid-resistant bricks and Acid-resistant tiles are widely used in lining of towers, tanks, tanks and tanks in petroleum, chemical industry, fertilizer, pharmaceutical industry, food manufacturing, paper-making, smelting, chemical fiber, electroplating room, laboratory and power generation, gas and other industries, and in working places such as underground sewage passages and open-air floors, their corrosion resistance can be exerted.

Technical Parameter of Acid Resistant Brick:

| Item | Unit | Index | Standard |

| Bulk Density | g/cm3 | 2.31-2.4 | HG/T3210-2002 |

| Water absorption | % | ≤0.5 | GB/T8488-2001 |

| Acid resistant degree | % | ≥99.8 | GB/T8488-2001 |

| Anti bending strength | Mpa | ≥58.8 | GB/T8488-2001 |

| Theraml stability | 130℃-20℃ | Not crack, exfoliate and other damage phenomena | GB/T8488-2001 |

| Note:Produced according to customer requirment | |||

Chemical Composition:

| SiO2 | 69.8 |

| Al2O3 | 22.5 |

| K2O | 2.7 |

| Na2O | 0.95 |

| CaO | 0.82 |

| MgO | 0.12 |

| Fe2O3 | 0.49 |

| Acid resistant degree | 99.8 |

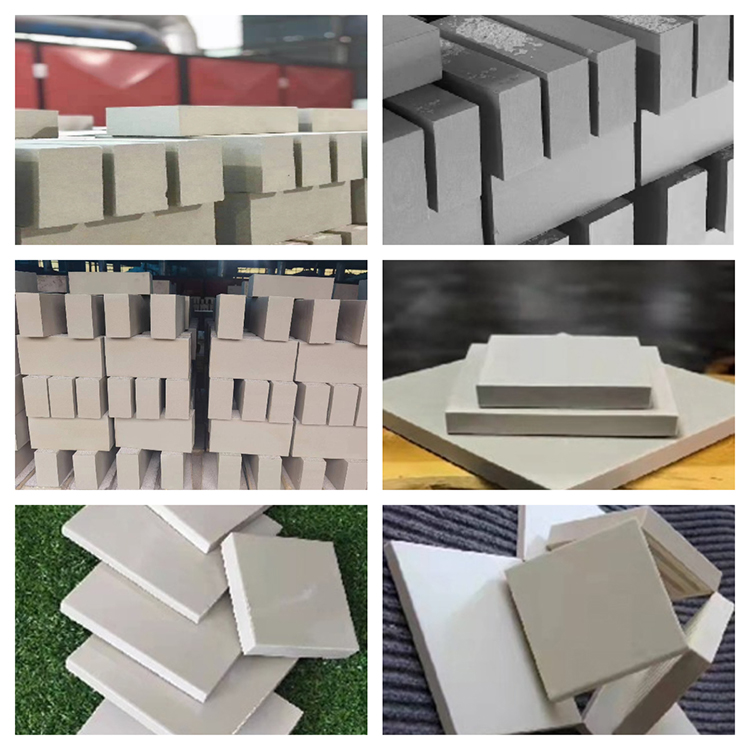

Size:

| Size | Pc/m2 | Unit weight/pc,kg |

| 150*75*15mm | 88 | 035 |

| 150*75*20mm | 88 | 0.5 |

| 150*75*30mm | 88 | 0.75 |

| 150*150*15mm | 44 | 0.75 |

| 150*150*20mm | 44 | 1 |

| 150*150*30mm | 44 | 1.5 |

| 200*200*15mm | 25 | 1.4 |

| 200*200*20mm | 25 | 1.8 |

| 200*200*30mm | 25 | 2.7 |

| 300*300*15mm | 11 | 3 |

| 300*300*20mm | 11 | 4 |

| 300*300*30mm | 10 | 6 |

| 230*113*15mm | 38 | 0.9 |

| 230*113*20mm | 38 | 1.2 |

| 230*113*30mm | 38 | 1.8 |

| 230*113*40mm | 38 | 2.5 |

| 230*113*65mm | 38 | 4 |

Packing & Shipping

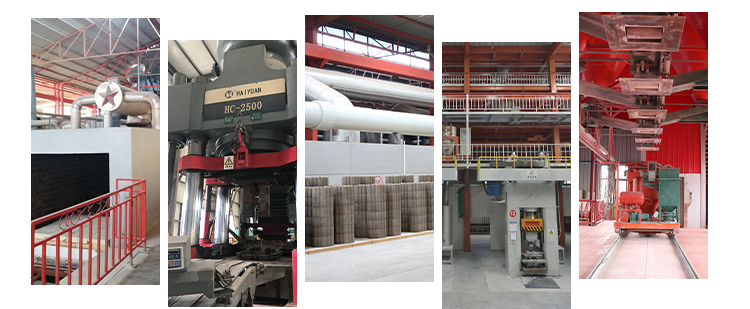

Company Information

Our Workshop

Customer Visit

Why choose us?

1.Abundant Experience. Rongsheng Group have over 20 years experience in the refractory industry and we have a deep understanding of the materials and applications we work with. We can provide expert advice and guidance to help customers find the best solutions for their needs.

2.Quality products. We pride ourselves on providing high-quality refractory products that are made to last. Our materials are carefully sourced and tested to ensure they meet our strict standards.

3.Competitive Price. We offer competitive pricie on all of our products without sacrificing quality and make the products competitive in your market.

4.Customization. We understand that every customer is unique, which is why we offer customized solutions tailored to their specific requirements. Whether it’s a custom shape or size, we can work with customers to create the ideal product for their application.

5.Safety. We take safety seriously and ensure that all of our products meet safety standards. Safty packing, prompt delivery time, and excellent after-sales services.

6.Large stocks. With a large stock of products on hand, we can better serve our customers, save money, and gain a competitive edge in their industry.

7. Overall solutions. We offer optimal and comprehensive solutions to supply the necessary refractory material for your high temperature kiln.

8.Long-term relationships. We believe in building long-term relationships with our customers based on trust and mutual benefit. We are committed to providing ongoing support and service to ensure customer satisfaction. Rongsheng Refractory can be used in many fields of steel, nonferrous metals, glass, cement, ceramic, petrochemical, machinery, boiler, light, and power industries. What’s more, Industrial distributors, refractory contractors, sales agents, trading companies, and refractory consultants can all benefit from promoting and selling our top-of-the-line refractory products. With a focus on durability, longevity, and performance, our products are designed to exceed your expectations and provide your customers with the best possible results.

So choosing us is the right choice for you.If you are interested in our products or if you have any question, pls feel free to contact us at any time. We will reply as soon as possible.