Abstract:

In the aluminum industry, carbon baking furnaces play a crucial role. This article explores the structure of carbon baking furnaces, the importance of refractory materials, and how to select the right materials to ensure efficient operation and long-term stability.

Introduction to Carbon Baking Furnace

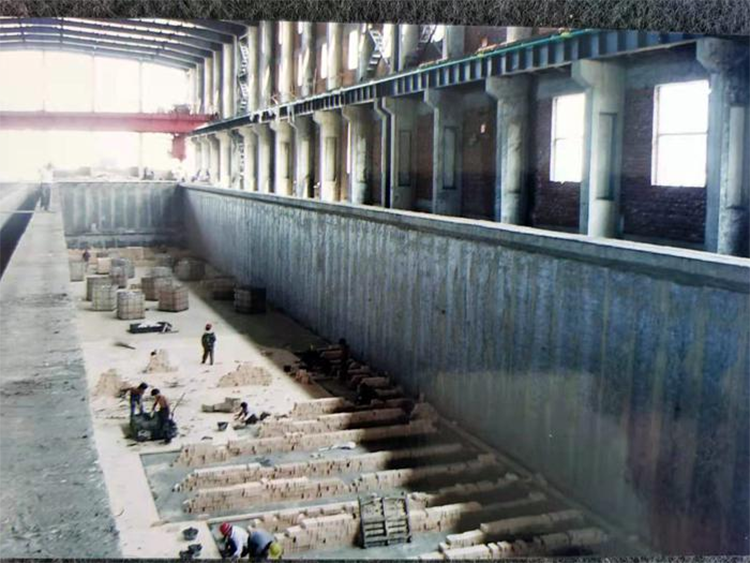

A carbon baking furnace is specialized thermal equipment used in the aluminum industry. It improves the electrical conductivity and thermal properties of carbon materials by heat-treating them in an oxygen-free environment, thereby enhancing the strength, oxidation resistance, and corrosion resistance of the products. This process is vital for the quality and production efficiency of aluminum products.

Classification of Carbon Baking Furnaces

Carbon baking furnaces are mainly divided into two types: open-type and covered-type. Open-type baking furnaces are primarily used for the production of anode carbon blocks for aluminum, while covered-type baking furnaces are suitable for the baking of cathode carbon blocks.

Importance of Refractory Materials

Refractory materials are central to the operation of carbon baking furnaces. They form the primary structure of the furnace and directly impact its lifespan and energy efficiency. The usage of refractory materials in such furnaces can range from 10,000 to 20,000 tons.

Composition and Selection of Refractory Materials

The selection of refractory materials should adhere to these principles:

①The furnace bottom refractory materials should have high compressive strength and a high load-softening temperature.

②Depending on temperature variations, different thermal conductivity lightweight insulation refractory materials should be selected.

③Typically, refractory materials consist of dense low-porosity clay bricks, mullite lightweight insulation bricks, high alumina lightweight insulation bricks, and large prefabricated furnace bottom bricks.

Performance Requirements for Refractory Materials

Refractory materials must meet the following performance criteria:

①Low high-temperature creep rate to withstand long-term high temperatures.

②High load-softening point to ensure no deformation under high pressure.

③Good thermal shock resistance to cope with periodic temperature changes.

Refractory Materials for Flue Walls and Cross Walls

The selection of materials for flue walls and cross walls is particularly critical, as they endure high temperatures, high pressure, and periodic temperature fluctuations over long periods. These parts require materials with excellent high-temperature stability and resistance to deformation.

The Key Role of Connection Bricks

Connection bricks are key materials in the baking furnace, linking two flues to enhance the overall integrity of the furnace. These bricks need to have high flexural strength at high temperatures, good thermal shock resistance, and a high load-softening point.

Innovation in Top Prefabricated Blocks

To reduce furnace surface temperature and heat loss, a new type of furnace surface prefabricated block has been developed. This block features a lightweight cast layer on top of the original refractory castable prefabricated block, effectively improving the operating environment.

Standardization of Refractory Materials

According to the YB/T 4444-2014 standard, refractory bricks are classified into three types: HQZ, HDZ, and HLZ, each with specific chemical compositions and physical performance indicators.

Conclusion

Selecting the right refractory materials is crucial for ensuring the efficient operation of carbon baking furnaces. At Henan Rongsheng Xinwei New Materials Research Institute Co., Ltd., we offer refractory materials that are meticulously designed and rigorously tested to meet the demands of baking furnaces of various scales and requirements. As a national high-tech enterprise, we are dedicated to continuous innovation and are committed to providing advanced, efficient, energy-saving, safe, and environmentally friendly high-performance refractory materials and system solutions for the global high-temperature industry. Together, we strive to support the development of the aluminum industry with the highest quality products and services.

About Us

Henan Rongsheng Xinwei New Materials Research Institute Co., Ltd., headquartered in Zhengzhou City, Henan Province, is affiliated with Henan Rongsheng Technology Group. As a national high-tech enterprise, we specialize in the R&D, production, and technical services of high-performance refractory new materials. Our focus on continuous innovation drives us to provide advanced technology, high-efficiency, energy-saving, safe, and environmentally friendly high-performance refractory materials and system solutions for the global high-temperature industry.