Aluminum Silicate Ceramic Fiber Blanket

Aluminum silicate ceramic fiber blanket, also known as aluminum silicate fiber blanket, is a common external insulation material. Below is a detailed introduction:

1. Main Raw Materials and Manufacturing Process

The main raw materials for aluminum silicate ceramic fiber blankets include hard clay clinker, bauxite, and alumina silicate powder. These inorganic materials are strictly selected and proportioned to ensure the basic performance of the product. The manufacturing process mainly includes the following steps:

- Melting: The raw materials are heated to a molten state at high temperatures, typically using resistance furnaces or electric arc furnaces.

- Spinning or Fiberizing: The molten materials are converted into fibers by spinning or fiberizing methods. The spinning method uses special nozzles to stretch the molten liquid into continuous long fibers, while the fiberizing method uses centrifugal force to fling the molten liquid into fibers on high-speed rotating rollers.

- Solidification: The fibers are rapidly solidified by cooling equipment to maintain their shape and stability.

- Molding: The fibers are sent into forming equipment, where processes such as needle punching, heat-setting, vertical and horizontal cutting, and winding are applied to create aluminum silicate ceramic fiber blankets with a certain strength and thickness. Among these, the needle-punching process uses a needle-punching machine to tightly interweave the fiber layers, significantly improving the blanket’s tensile strength and wind erosion resistance.

- Refractory Treatment: To further enhance the product’s high-temperature performance and service life, the fiber blanket undergoes a refractory treatment, such as coating or soaking with refractory materials.

- 2. Main Characteristics

- Yüksek Sıcaklık Dayanımı: Aluminum silicate ceramic fiber blankets can withstand temperatures up to 1100°C, and certain specific types, such as the 1400 high-alumina type, can withstand temperatures up to 1400°C. This characteristic enables the fiber blankets to maintain stable physical and chemical properties in high and ultra-high temperature environments.

- Good Insulation Properties: The thermal conductivity of aluminum silicate ceramic fiber blankets is low, effectively reducing heat transfer, lowering energy consumption, and improving the thermal efficiency of industrial equipment.

- Sound Absorption and Noise Insulation: The uniform fiber structure inside the aluminum silicate ceramic fiber blankets provides excellent sound absorption and noise insulation effects.

- Strong Chemical Stability: These blankets are not easily reactive with common chemicals and have strong resistance to corrosive media such as acids and alkalis, maintaining stable performance in harsh chemical environments.

- Lightweight and Flexible: With a density ranging from 96 to 200 kg/m³, aluminum silicate ceramic fiber blankets are lightweight and soft, causing minimal load on equipment. Additionally, they have good flexibility and plasticity, making them easy to cut and assemble as needed, simplifying installation.

- Standard Sizes: Aluminum silicate ceramic fiber blankets come in uniform sizes, which facilitate cutting and installation. The common widths are 610mm and 1220mm, with thicknesses customizable according to customer needs, such as 20mm, 30mm, and 50mm.

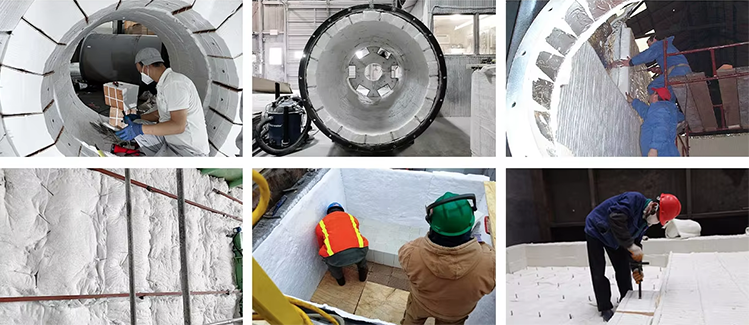

3. Applications

3. Applications

Due to its many advantages, aluminum silicate ceramic fiber blankets have a wide range of applications:

- Industrial Sector: Used for thermal insulation in industrial furnaces, high-temperature pipelines, high-temperature kilns, hot air furnaces, drying ovens, vesaire., to reduce heat loss and improve production efficiency.

- Aerospace: Used in the thermal insulation systems of spacecraft.

- Petrochemical: Used for insulation in reactors and storage tanks in the petroleum and chemical industries.

- Other Sectors: Also used in electrical appliances, military, environmental protection, vesaire., as high-temperature insulating gaskets, high-temperature pipe insulation pads, and more.

In conclusion, aluminum silicate ceramic fiber blankets are an excellent, widely used inorganic non-metallic material that brings convenience and benefits to both industrial production and daily life.