Refractory Material Solution For Glass Furnace

Glass furnace refractories are the unsung heroes of the glassmaking industry, playing a vital role in ensuring the efficiency, durability and safety of high-temperature processes. Requirements of refractories are various and decided by the furnace working condition and actual atmosphere. But they should character with these features: high temperature resistance, good chemical stability and anti-corrosion, thermal shock resistance, volume stability, mechanical strength.

Rongsheng Refractory Factory provide glass melting furnace customers with the customize refractory material used in the glass melting furnace. For the latest refractory bricks for glass furnace information and quotations, please contact us.

Our refractory materials products which are used in the glass industry with cheap price are different from those in the steel industry. The refractories used in glass kins are mainly divided into fused materials, siiceous materials and magnesia malerials such as fused AZS bricks, silica bricks, high-grade sintered magnesia bricks, Fused and Re-sintered magnesia brick, magnesite chrome refractory bricks(fused rebonded, fused semi-rebonded, directly Bonded), fire clay bricks, ultra-high alumina bricks, sillimanite bricks, mullite bricks, fused mullite bricks, Zirconium corundum bricks, fused corundum bricks, zirconium-containing refractory bricks, unshaped refractories(refractory castable, light weight insulation castable, ramming mass), insulation materials(light weight high alumina brick, mullite insulation brick) , various refractory mortar and light weight insulation products(calcium silicate board, aluminum siicate fiber insulation material, rock wool board, composite silicate board) vesaire.

Refractory Selection for Glass Furnace

As we know, furnace lifetime depends directly on refractory quality. While refractory selection, important factors should be Considered.

1.Temperature resistance and Corrosion resistance

2.Thermal shock resistance and Thermal expansion

3. Thermal conductivity and Mechanical resistance

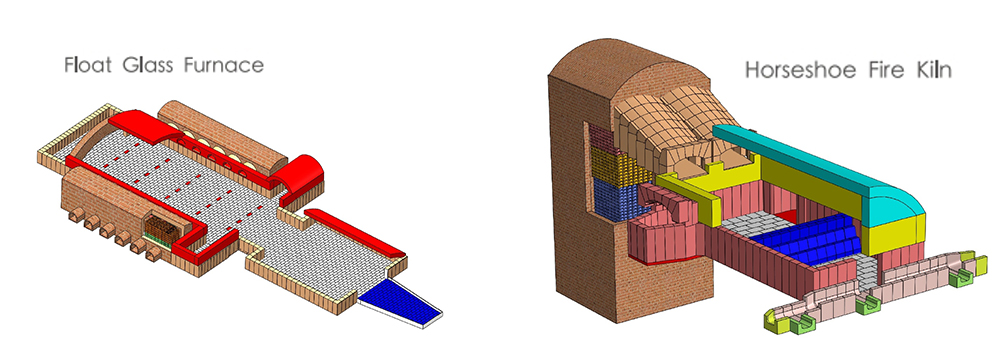

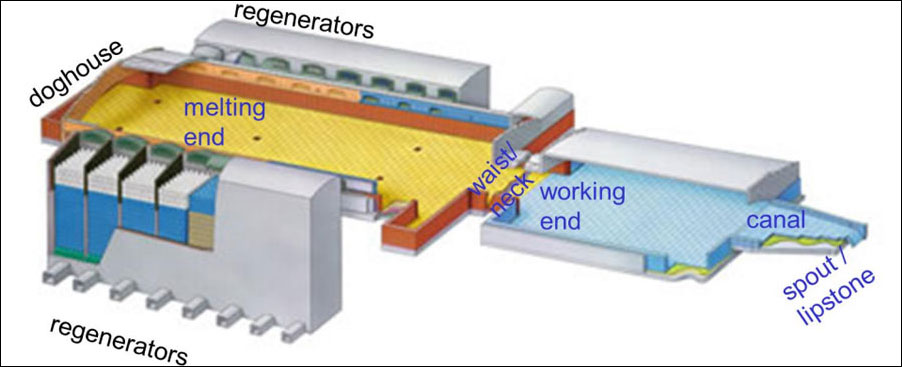

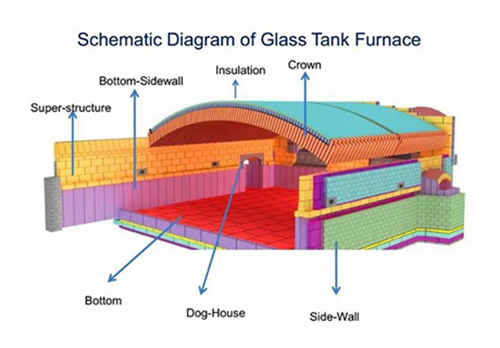

Refractory Selection of Glass Furnace is mainly made up of Regenerator Checker, Wall, Crown & Bottom, Doghouse Wall, Burner, Melting Pool Sidewall, Corner, Crown & Bottom, Gable, Suspended Arch, Working Pool Crown, Sidewall, Bottom & Tuyere, Tin Bath Bottom and Tin Bath Roof, for different part of glass furnace, different refractory brick should be used, the detailed application as below.

1. Regenerator Checker, Wall, Crown & Bottom usually used Magnesia Refractory Brick, Magnesia-Chromite Refractory Brick, Magnesia-Zirconia Refractory Brick, Magnesia-Alumina Refractory Brick, Megnesia-Silica Refractory Brick, Light Weight Magnesia-Silica Brick, Chamotte Refractory Brick, Silica Refractory Brick and Sillimanite Refractory Brick.

2. Melting Pool Sidewall, Corner, Crown & Bottom usually useFused Cast AZS Refractory Brick, Fused Cast AZS Bottom Block, Fused Cast b-Alumina Brick, Zirconia-Mullite (Zirmul) Brick, Silica Refractory Brick,Corundum-Zirconia-Mullite Ramming Mix and Zirconia Mullite Ramming Mix.

3. Working Pool Crown, Sidewall, Bottom & Tuyere usually useFused Cast AZS Refractory Brick, Fused Cast AZS Bottom Block, Fused Cast a-b Alumina Brick, Fused Cast b-Alumina Brick, Zirconia Refractory Brick, Silica Refractory Brick, Corundum-Zirconia-Mullite Ramming Mix and Zirconia-Mullite Ramming Mix.

4. Burner usually used Fused Cast AZS Refractory Brick,Fused Cast a-b Jargal Block and Sintered Zirconia Refractory Brick. Doghouse Wall usually useSilica Refractory Brick; Gable usually used Zirconia Refractory Brick and Silica Refractory Brick.

5. Suspended Arch usually usedFused Cast AZS Refractory Brick, Zirconia-Mullite Brick and Silica Refractory Brick. Tin Bath Bottom & Roof usually usedFused Cast AZS Refractory Brick and Sillimanite Refractory Brick.

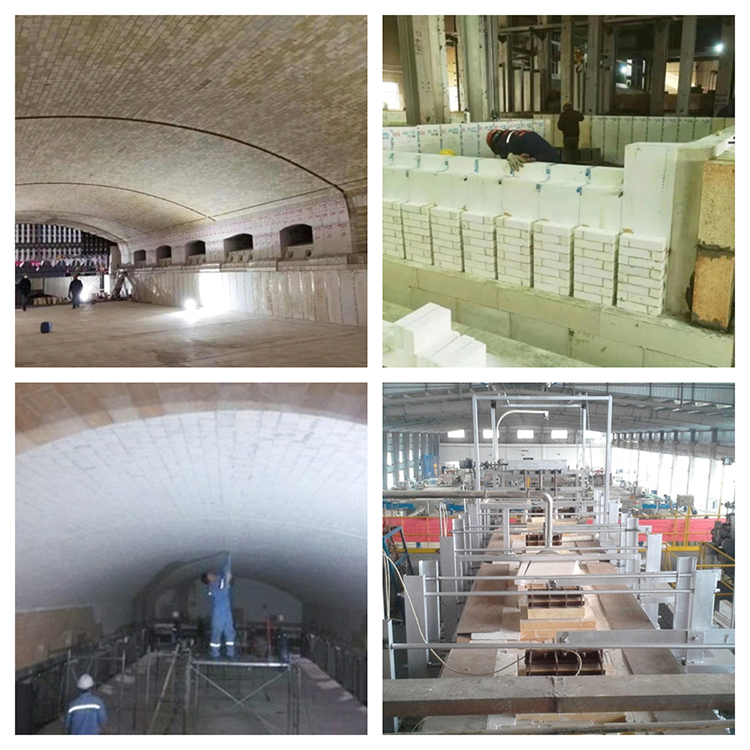

Glass Kiln Construction Photos

Rongsheng Refractory Group has more than 20 years professional manufacturing and exporting experience, which will be your best choice to buy high quality and suitable refractory bricks at low price for your furnace or kiln. You can contact us to visit our refractory factory or can send us an inquiry email for price list. Welcome to know more about refractory Bricks for glass furnace.

Zirconia Refractory Brick

Zirconia Refractory Brick Magnesia Zirconia Brick

Magnesia Zirconia Brick