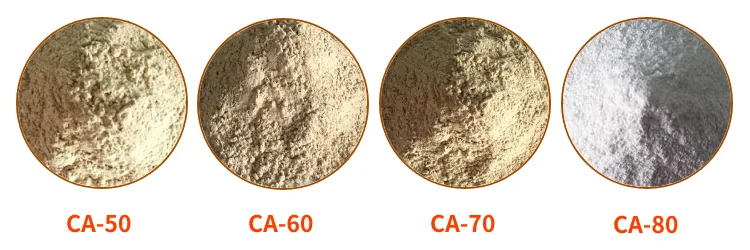

Product Description of High Alumina Refractory Cement CA50 CA60 CA70 CA80

High Alumina Refractory Cement/Calcium Aluminate Cement/Aluminate Cement are collectively referred to as refractory cement. High alumina cement (formerly known as bauxite cement) is a hydraulic cementing material made of high-purity calcium materials and high-purity alumina as the main raw materials, and clinker with alumina content of about 50%.According to the different content of Al2O3,they can have totally foue types:CA50,CA60,CA70 and CA80.

CA-50, CA-70, CA-80, the alumina content is greater than 48%, 68% and 77% respectively. Its refractoriness is greater than 1650°C. The use temperature can reach 1800℃, and the impurity content is lower than other common cements.

Product Features of High Alumina Refractory Cement CA50 CA60 CA70 CA80

1.High refractoriness, up to 1650℃±50℃;

2.High density, low porosity.

3.High strength and wear resistance.

4.Good thermal exfoliation.

5.Good resistance to slag invasion;

6.Good plasticity and convenient construction;

7.High bonding strength

8.Good thermal shock stability.

Our Advantages of High Alumina Refractory Cement

1.More than 15 years manufacturer and supplier of High Alumina Refractory Cement

2.Low MOQ, Fast Delivery in 10 to 20 days.

3.High quality guarantee and factory directly sale affordable price

4.Ligne de production réfractaire intelligente entièrement automatique, livraison à l'échelle nationale.

5.Fournir des services de conseil et personnaliser profondément les solutions globales

Product Application of High Alumina Refractory Cement

The application industries of refractory cement include metallurgy, building materials, machinerie, petrochemicals, ceramics, verre, boilers, electricity, steel, ciment, etc. Mainly used in coke ovens, glass furnaces, blast furnace hot blast furnaces, and other industrial kilns.

Refractory cement is a high-quality binder that can be used to make high-performance low cement and high aluminum castables, refractory concrete, ramming materials, gunning materials, and other castables, or unshape block refractory materials used under high temperature, high pressure, and reducing conditions.Used for building or repairing various high-strength insulation or acid resistant kilns, etc.

Product Specification of High Alumina Refractory Cement

|

Article

|

High Alumina Cement

|

|||||

|

CA50

|

CA65

|

CA70

|

CA75

|

CA80

|

||

|

Al2O3%≥

|

50

|

64-66

|

69-71

|

73-75

|

77-80

|

|

|

Fe2O3%≤

|

2.5

|

0.8

|

0.7

|

0.6

|

0.5

|

|

|

SiO2%≤

|

7.5

|

1.2

|

1

|

0.8

|

0.5

|

|

|

R2O%≤

|

0.4

|

0.4

|

0.4

|

0.4

|

0.4

|

|

|

Cl%≤

|

0.1

|

0.1

|

0.1

|

0.1

|

0.1

|

|

|

S%≤

|

0.1

|

0.1

|

0.1

|

0.1

|

0.1

|

|

|

325 mesh remind≤

|

12

|

5

|

5

|

5

|

5

|

|

|

Surface(m2/kg)≥

|

320

|

380

|

400

|

430

|

450

|

|

|

Initial Setting Time, min≥

|

60

|

120

|

120

|

120

|

120

|

|

|

Final Setting Time, min≤

|

360

|

420

|

420

|

420

|

420

|

|

|

Crushing Strength, MPa≥

|

1day

|

55

|

45

|

40

|

35

|

30

|

|

3days

|

65

|

55

|

50

|

45

|

40

|

|

|

Bending Strength, MPa≥

|

1day

|

6.5

|

5.8

|

5.5

|

5.2

|

5

|

|

3days

|

7.5

|

6.7

|

6.5

|

6.3

|

6

|

|

|

Refractoriness (°C)

|

1650

|

1680

|

1730

|

1750

|

1770

|

|

Packing and Shipping of High Alumina Refractory Cement