What is a Carbon Baking Furnace?

A carbon baking furnace is a specialized high-temperature industrial kiln used for the baking (or firing) of carbon-based products such as:

-

Graphite electrodes

-

Carbon anode blocks

-

Cathode blocks

-

Carbon bricks

The main purpose of carbon baking is to:

-

Remove volatile substances from green carbon bodies

-

Increase product density, mechanical strength, and electrical conductivity

-

Ensure carbon products achieve the desired physical and chemical properties

Common Types of Carbon Baking Furnaces:

-

Ring-type Baking Furnace

-

Tunnel-type Baking Furnace

-

Box-type Baking Furnace

Operating Conditions:

-

Working temperature: typically between 1000°C to 1400°C

-

Atmosphere: mostly reducing atmosphere (rich in CO and hydrocarbons)

-

Environment: high thermal loads, gas corrosion, and mechanical wear

Refractory Bricks Used in Carbon Baking Furnaces

Due to the demanding working conditions inside carbon baking furnaces, the refractory materials must offer:

-

Excellent high-temperature resistance

-

Strong thermal shock resistance

-

Good chemical stability in reducing atmospheres

-

Resistance to tar vapors and gas corrosion

-

High density and low porosity to minimize infiltration

Main Types of Refractory Bricks:

| Furnace Area | Recommended Refractory Brick Types | Key Properties |

|---|---|---|

| Furnace Walls and Roof | High Alumina Bricks (55-75% Al₂O₃) | High refractoriness, good thermal shock resistance, excellent corrosion resistance |

| High-Temperature Roof Zone | Silica Bricks | High strength at elevated temperatures, good structural stability |

| Flame Impact Zones | Mullite Bricks, High Alumina Bricks | Excellent resistance to flame erosion and thermal cycling |

| Furnace Door and Openings | High Alumina Bricks with Silicon Carbide Plates | Enhanced abrasion and thermal shock resistance |

| Baking Channels and Floor | Silicon Carbide Bricks (SiC Bricks) | Outstanding wear resistance, fast thermal conductivity, superior resistance to slag buildup |

| Furnace Foundation | Fireclay Bricks | Economical solution for lower temperature zones |

| Insulating Layer (Backup) | Lightweight High Alumina or Fireclay Insulating Bricks | Effective thermal insulation, energy savings |

Key Characteristics of Each Refractory Material:

-

High Alumina Bricks:

-

High refractoriness over 1700°C

-

Strong resistance to chemical attack

-

Good load-bearing performance

-

-

Silica Bricks:

-

Exceptional strength at temperatures above 1400°C

-

Good volume stability under high heat

-

Best for furnace roofs that remain consistently hot

-

-

Mullite Bricks:

-

Excellent thermal shock resistance

-

High mechanical strength and thermal stability

-

Ideal for critical flame-impacted areas

-

-

Silicon Carbide Bricks:

-

High thermal conductivity

-

Exceptional abrasion resistance and anti-slagging properties

-

Good performance under reducing atmospheres

-

-

Fireclay Bricks:

-

Suitable for non-critical, lower temperature areas

-

Good workability and cost-effectiveness

-

-

Lightweight Insulating Bricks:

-

Low thermal conductivity

-

Significant reduction in energy consumption

-

Lightweight and easy to install

-

Special Considerations for Carbon Baking Furnace Refractories

-

Resistance to Tar Vapor Corrosion:

Tar vapors can condense and infiltrate refractory structures, leading to chemical degradation.

➔ Dense-structured, low-porosity bricks are recommended. -

Performance in Reducing Atmospheres:

Reducing gases like CO can chemically attack traditional silica-bonded bricks.

➔ Select refractories with stable crystal phases and minimal reactive binders. -

Thermal Shock Resistance:

Frequent heating and cooling cycles can cause cracking and spalling.

➔ Choose materials like mullite bricks and silicon carbide bricks with excellent thermal cycling endurance.

About Rongsheng Refractory Factory

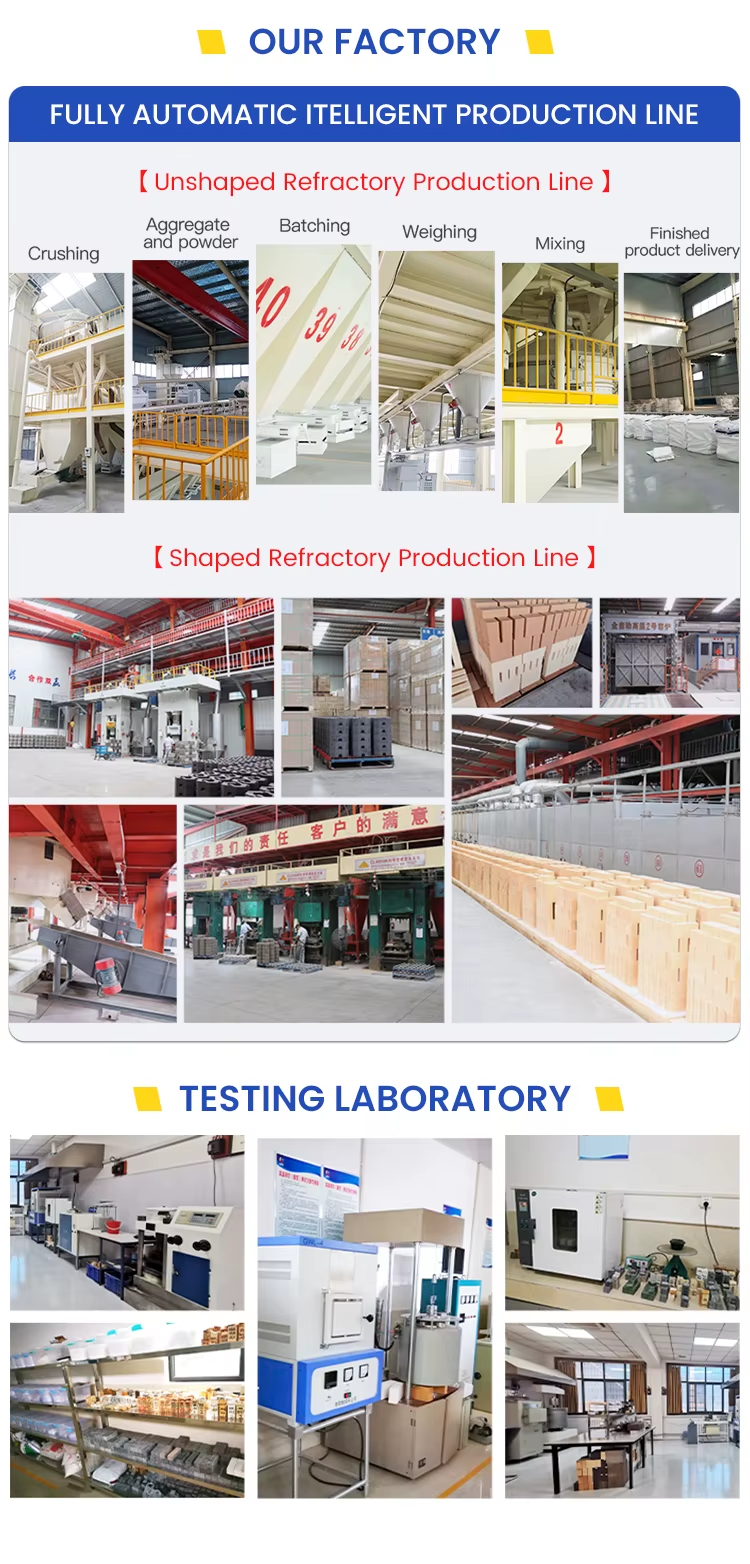

Rongsheng Refractory have been the Leading manufacturer, Supplier & Exporter of top-quality refractory materials for more than 20 years. Our product range includes high alumina bricks, corundum bricks, azs bricks, magnesia bricks, fire clay bricks, insulating bricks, and unshaped materials such as refractoy castable, refractory cement, refractory motar, refractory ramming mass, refractory Spraying Mass, Refractory Plastic, etc. Our diverse product range caters to 90% of the refractory needs in industries like Iron & Steel Industry, Cement Industry, Non-ferrous Industry, Power Industry, Petrochemical Industry and Glass Industry. And our products are exported to more than 100 countries and regions all over the world. We are renowned as one of the top refractory brick supplier and refractory material supplier in the industry.

As professional refractory material supplier and manufacturer, Rongsheng Refractory Usine is located in Xinmi city, the “Capital of Refractory” in China. We specialize in refractory products for nearly 15 years, covering a full range of shaped and unshaped refractory products, such as High Alumina Series Bricks, Mullite Bricks, Corundum Series Bricks, Silica Series Bricks, Andalusite Bricks, Magnesia Series Brick, Carborundum Brick, Insulating Series Brick, Insulating and Dense Castables, also other related products for more sophisticated applications. We are recognized as a top fire brick factory and refractory material supplier.

Certificates of Rongsheng Refractory Group

Rongsheng Group holds several international certifications, including ISO9001, ISO14001, OHSAS18001, CE, and SGS. We also have numerous domestic certifications. As a top refractory company and refractory suppliers, we are dedicated to innovation and customer satisfaction. We collaborate with universities to establish research and development centers, providing customers with differentiated, serialized, and customized refractory products and services.

Professional Sales Team

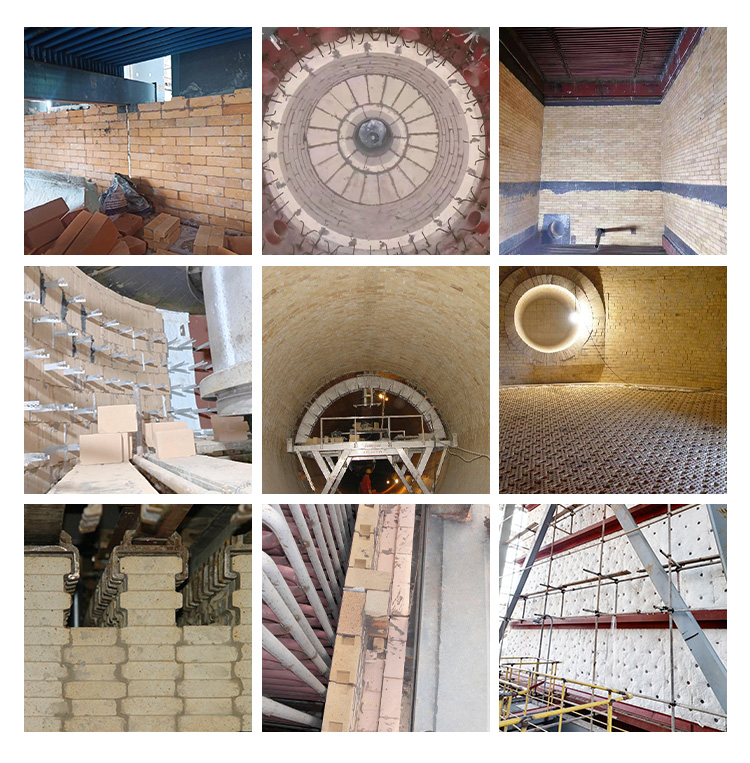

Engineering Case

Customer Visit

Join our satisfied customers from over 100 countries and regions who trust Rongsheng Refractory for their needs. As a leading refractory brick manufacturers and refractory material supplier, we are here for you at any time. Welcome your inquiry.

Conclusion

Choosing the right refractory bricks for a carbon baking furnace is critical to ensuring operational efficiency, extending service life, and maintaining product quality.

Rongsheng Refractory offers a full range of premium refractory solutions tailored for carbon baking furnaces, combining high performance, reliability, and cost-effectiveness.

For professional technical support and customized refractory solutions, please contact us:

Tel/WhatsApp: +86-13903810769

E-mail: enquête@rsrefratorychina.com

Website: https://rsrefractorychina.com