Description of Good Price Hot Sale High Alumina Refractory Bricks Alumina Fire Brick For Kiln Furnace

High alumina refractory brick manufactured from Rongsheng Refractory is a kind of alumina-silicate refractory material with content of alumina oxide more than 48%. It is calcined and formed by the raw material of bauxite or the material with high content of AL2O3. High thermal stability, the refractoriness is more than 1770℃. Good slag resistance, used for the liner of masonry steel-making electric stove, glass furnace and cement revolver.

If Al2O3 content of High alumina refractory brick is higher than 90%, it is called corundum brick. Due to different resources, the standards of different countries are not completely consistent. For example, in European countries, the lower limit of Al2O3 content for high alumina refractories is 42%. In China, Al2O3 content in high alumina brick is generally divided into three grades: Grade I – Al2O3 content > 75%; grade II – Al2O3 content is 60-75%; grade III – Al2O3 content is 48-60%.

Looking for the best high alumina brick supplier that combine exceptional quality and cost-efficiency? Look no further! Rongsheng Refractory Company, a more than 20 years leading refractory fire bricks manufacturer in China, specializes in producing premium-grade high alumina fire bricks at competitive prices. Thanks to China’s abundant high-quality refractory raw materials, we deliver top-performing fire bricks that meet the most demanding industrial standards while helping you significantly reduce costs.

Whether you need durable, heat-resistant solutions for your kiln, furnace, or any high-temperature application, Rongsheng Refractory Company is your reliable partner. Don’t miss the opportunity to optimize your operations and save on expenses. Contact us today and send inquiry right now for a customized quote and discover why global customers trust us for their refractory needs.

Good Price High Quality Assured High Alumina Refractory Bricks For Sale

Rongsheng Refractory Company are more than 20 years leading refractory bricks manufacturer and exporter from China. Our High Alumina Bricks have the best quality at the most competitive alumina bricks price worldwide. We support customizable products & solutions as customers’ requirements. All of all refractory products are timely delivery. We export in Dubai, Abu Dhabi, Jeddah, Riyadh, UAE, Algeria, Sri Lanka, Nepal, Bangladesh, Vietnam, Maldives, Malaysia, Dammam, Bahrain, Qatar, Oman, South Africa, Ghana, Ethiopia, Sudan, Nigeria, Egypt, Kuwait, Fujairah, Thailand, Philippines, Papua New Guinea, Indonesia, Bhutan, Congo, Tanzania, Namibia, Botswana, Brazil, Chile, Bolivia, Peru, Colombia, Venezuela, Suriname, Argentina and all over the world. Compared to other firebrick manufacturers, Rongsheng Refractory has over 20 Years experience and we manufacture and supply superior quality high alumina fire bricks and other refractory materials such as refractory castables, refractory mortars, low and ultra low refractory cements, high alumina castable, all types of ramming mass.

If you have any specific requirements or need a price quotation for our High Alumina Refractory Bricks, please don’t hesitate to reach out to us. Our dedicated sales team is ready to assist you with any inquiries or requests you may have at any time. So send inquiry to us, get best high alumina bricks price right now.

Features of High Alumina Bricks From High Alumina Brick Manufacturer

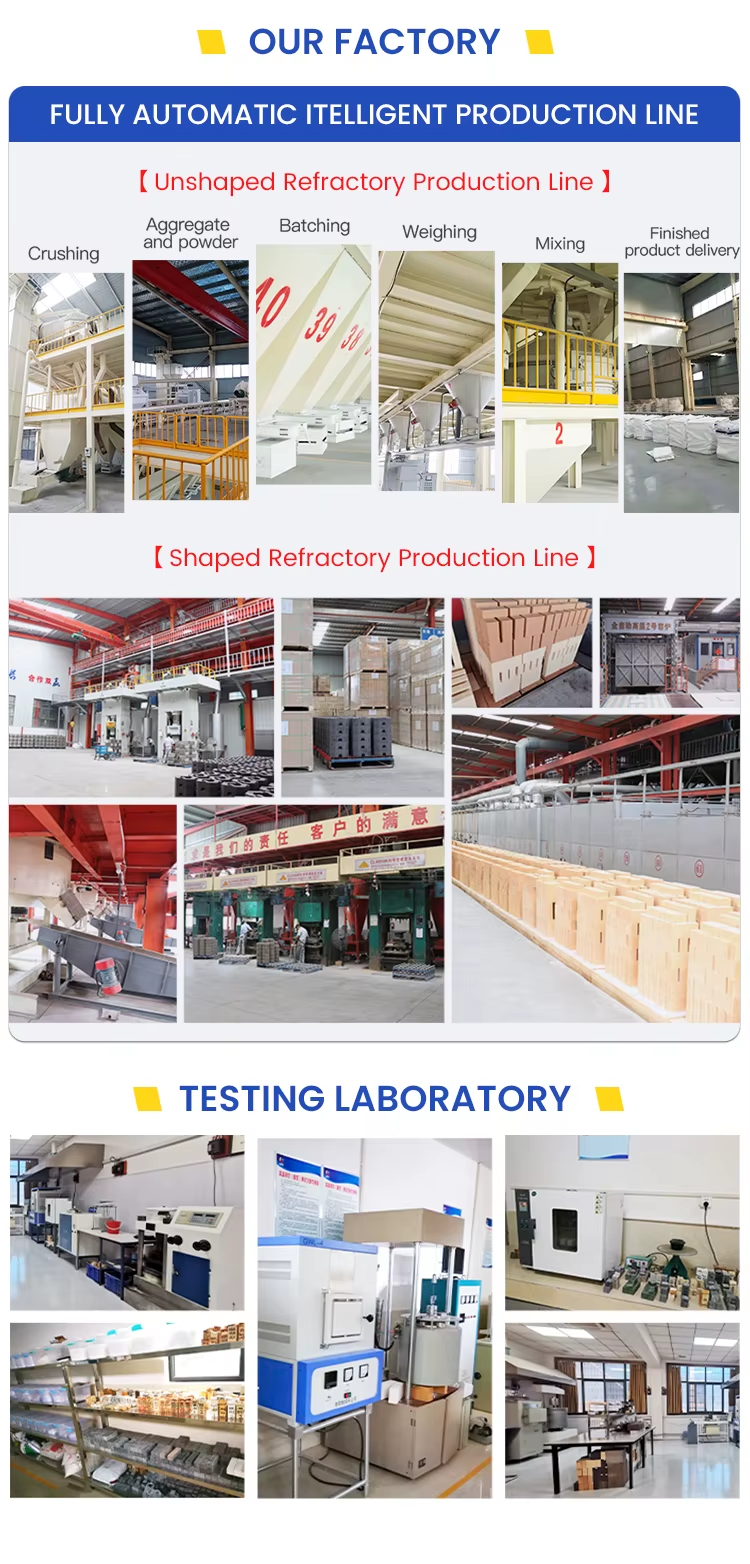

Rongsheng Refractory Factory

1. Good thermal conductivity

2. High temperature strength

3. Good slag resistance, acid and alkali resistance.

4. High thermal stability

5.Al2O3 Content(%): 48%~85%

6.Low apparent porosity

Application Of Rongsheng Refractory High Alumina Refractory Bricks

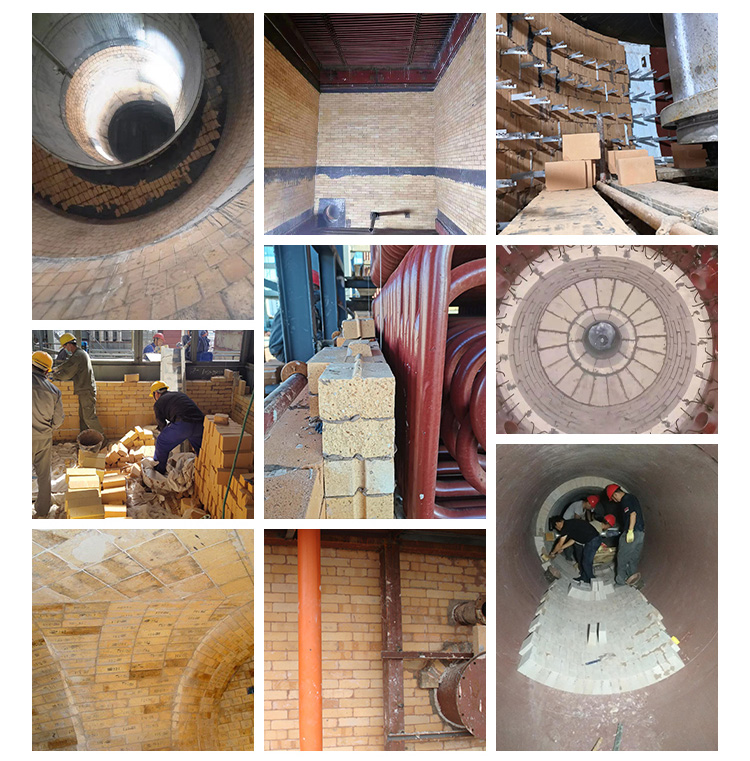

High alumina bricks are widely used in various industries and applications. These include steelmaking processes such as BOF converters, electric arc furnaces, steel ladles and Tundish. For cement production, High alumina bricks are essential in rotary kilns, meal pipes, kiln hoods and Inlet Chamber. In the aluminum industry, key applications include rotary furnaces, anode baking furnaces, and sidewell melters. In the field of boilers and incinerators, they are used in CFB boilers, grate-fired boilers, rotary kiln incinerators, and gasifiers, ensuring durability and efficiency in high-temperature environments. They are used in blast furnaces, Hot Blast Stove,Steel ladle lining, Reheating furnace, Cement kiln, Tunnel kiln,Chaudière, coke oven, carbon furnace, glass kiln , Steel smelting furnace and various kiln lining and thermotechnical equipment, etc. In addition, high alumina bricks can also be processed into open hearth regenerative grid bricks, socket bricks for pouring system, nozzle bricks, etc. according to the requirements of industrial furnaces.

Technical Data of High Alumina Refractory Bricks

| High Alumina Refractory Brick Physical and Chemical Index: | ||||||

| Article | Properties | |||||

| RS-80 | RS-75 | RS-65 | RS-55 | RS-48 | ||

| Al2O3 (%) | 80 | ≥75 | ≥65 | ≥55 | ≥48 | |

| Refractoriness (°C ) | ≥1790 | ≥1790 | ≥1790 | ≥1770 | ≥1750 | |

| Bulk density (g/cm3) | 2.65 | 2.5 | 2.45 | 2.4 | 2.3 | |

| Softening temperature under load (°C ) | 1530 | ≥1520 | ≥1500 | ≥1470 | ≥1420 | |

| Reheating Linear changes Rate (%) | 1500°CX2H | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 |

| 1450°CX2H | -0.4 | -0.4 | -0.4 | -0.4 | -0.4 | |

| Apparent porosity (%) | 22 | ≤23 | ≤23 | ≤22 | ≤22 | |

| Cold crushing strength (Mpa) | 55 | ≥50 | ≥45 | ≥40 | ≥35 | |

| Application | steel furnace, glass furnace, sodium silicate furnace, ceramic shuttle kiln, cement rotary kiln, blast furnace, electric furnace, blast furnace and reverberatory furnace. | |||||

Packing & Shipping

Wooden pallets with plastic film or according to your request.

1. Strong packing protects the goods from any possible damage during transit.

2. Solid packing and overall stuffing prevent the cases from vibration and jarring.

3. Necessary precaution is taken to protect goods from pilferage or rain.

Every possible precaution is taken to ensure our products in prime condition when reach customers around the world.By sea or air. Normally 7 to 14 Days for delivery, according to your order quantity.

Rongsheng Refractory Advantages

More Than 20 Years Experience Focus on refractories field

- 1.Rongsheng Refractory Factory Established for 20+ years

- 2.600000 Tons Annual Capacity

- 3.Own complete chain in the field of refractory

- 4.10+ Inspection Methods, Refractorness, Compressive strength, etc

- 5.Serving for 2000+ large enterprises

- 6.Cooperating with many China/World 500 companies

- 7.30+ Certificates, Patent, ISO, CE, MSDS, etc

- 8.Provide professional customized solutions

- 9.Provide after-sales warranty service

- 10.One-stop Service;

11.Professional after-sales team support and lifetime guarantee;

12.Supervision of quality-control team;

13.Customer-oriented and personalized solution service.

- Rongsheng Refractory has established complete quality system and conducted quality control through the whole staff and process that from raw materials, production, check and various parts strictly according to ISO9001 standard. Annual production capacity is up to 60000 tons. There are light and heavy weight materials production lines and all kinds of complete production, testing and check equipment, of which there are 10 series shaped press machine that from 400 tons to 1000 tons and two hyperthermia tunnel kilns whose length are 148m and 118m.

Engineering Case

Customer Visit

Pourquoi nous choisir?

1.Expérience abondante. Rongsheng Refractory Group have over 20 ans d'expérience dans l'industrie réfractaire et nous avons une connaissance approfondie des matériaux et des applications avec lesquels nous travaillons. Nous pouvons fournir des conseils d'experts et des conseils pour aider les clients à trouver les meilleures solutions pour leurs besoins.

2.Produits de qualité. Nous sommes fiers de fournir des produits réfractaires de haute qualité qui sont faits pour durer. Nos matériaux sont soigneusement sélectionnés et testés pour s'assurer qu'ils répondent à nos normes strictes.

3.Prix compétitif. Nous offrons des prix compétitifs sur tous nos produits sans sacrifier la qualité et rendons les produits compétitifs sur votre marché.

4.Personnalisation. Nous comprenons que chaque client est unique, c'est pourquoi nous proposons des solutions personnalisées adaptées à leurs besoins spécifiques. Qu'il s'agisse d'une forme ou d'une taille personnalisée, nous pouvons travailler avec les clients pour créer le produit idéal pour leur application.

5.Sécurité. Nous prenons la sécurité au sérieux et veillons à ce que tous nos produits répondent aux normes de sécurité. Emballage de sécurité, délai de livraison rapide, et d'excellents services après-vente.

6.Grands stocks. Avec un large stock de produits à portée de main, nous pouvons mieux servir nos clients, économiser de l'argent, et acquérir un avantage concurrentiel dans leur industrie.

7. Solutions globales. Nous proposons des solutions optimales et complètes pour fournir le matériau réfractaire nécessaire à votre four à haute température.

8.Relations à long terme. Nous croyons en la construction de relations à long terme avec nos clients basées sur la confiance et le bénéfice mutuel. Nous nous engageons à fournir un soutien et un service continus pour assurer la satisfaction de nos clients. Le réfractaire Rongsheng peut être utilisé dans de nombreux domaines de l'acier, Métaux non-ferreux, verre, ciment, céramique, pétrochimique, machinerie, Chaudière, lumière, et industries énergétiques. Quoi de plus, Distributeurs industriels, entrepreneurs réfractaires, agents de vente, sociétés commerciales, et les consultants réfractaires peuvent tous bénéficier de la promotion et de la vente de nos produits réfractaires haut de gamme. En mettant l'accent sur la durabilité, longévité, et performances, nos produits sont conçus pour dépasser vos attentes et offrir à vos clients les meilleurs résultats possibles.

Nous choisir est donc le bon choix pour vous. Si vous êtes intéressé par nos produits ou si vous avez des questions, pls n'hésitez pas à nous contacter à tout moment. Nous vous répondrons dès que possible.