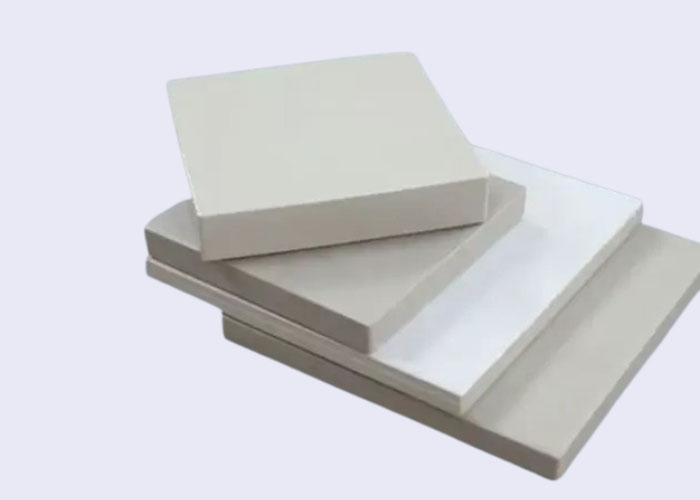

Product Description of Industrial Anti-corrosion Acid Resistant Ceramic Tiles For Chemical Industry

Acid resistance brick’s main material is quartz, feldspar, clay,its a corrosion-resistant material made by high temperature oxidative decomposition,it add a dovetail trough in back of the bricks ,so It is easy to be firmly bonded with acid-resistant mud during construction,not easy to falll off.It can guarantee project quality,at the same time it can extend the service life,It is an ideal anti-corrosion material for chemical industry, petroleum, electric power, chemical fertilizer, kimyasal elyaf, eritme,pharmaceutical, acid, alkali and other industries.

Features of Factory Price Industrial Ceramic Tiles Acid and Alkahi Resistance Bricks

1.Low water absorption

Because acid resistant brick is made of quartz, clay and other materials, so it ‘s simillar with ordinary bricks, the ability to absorb water is very low, can be used as a waterproof floor decoration material.

When choosing tiles, waterproof performance is one of the important reasons for consumers to choose it, especially in the ground where there is often water, it can play a good protective role, and it will basically be used.

2.Strong acid and alkali resistance

Why the acid-resistance brick has strong acid and alkahi resistance?

Beause the raw material is SIO2,Silica is resistant to corrosion,and it also have low water absorption,It’s not easy for liquids to penetrate inside,therefore, corrosion of alkaline substances of various concentrations can be prevented in the normal temperature.

3.Long Service Life

Acid-resistant brick compare with ordinary bricks its strength is higher , it has a pressure capacity of more than 100MPA, to ensure that the strong impact and high frequency of trampede will not be easily damaged, does not affect our long-term use.

One of the characteristics of acid-resistant brick ensures that it can still be intact in long-term use without aesthetic problems.

Aside Dayanıklı Tuğla Teknik Parametre

| Öğe | Birim | dizin | Standart |

| Kütle yoğunluğu | g/cm3 | 2.31-2.4 | HG/T3210-2002 |

| Su soğurumu | % | ≤0,5 | GB/T8488-2001 |

| aside dayanıklı derece | % | ≥99,8 | GB/T8488-2001 |

| Anti bükülme gücü | Mpa | ≥58,8 | GB/T8488-2001 |

| Termal kararlılık | 130℃ -20 ℃ | çatlamaz, pul pul dökülme ve diğer hasar olayları | GB/T8488-2001 |

| Not:Müşteri isteğine göre üretilir | |||

Kimyasal bileşim

| SiO2 | 69.8 |

| Al2O3 | 22.5 |

| K2O | 2.7 |

| Na2O | 0.95 |

| CaO | 0.82 |

| MgO | 0.12 |

| Fe2O3 | 0.49 |

| aside dayanıklı derece | 99.8 |

Boyut:

| Boyut | adet/m2 | birim ağırlık/adet,kilogram |

| 150*75*15mm | 88 | 035 |

| 150*75*20mm | 88 | 0.5 |

| 150*75*30mm | 88 | 0.75 |

| 150*150*15mm | 44 | 0.75 |

| 150*150*20mm | 44 | 1 |

| 150*150*30mm | 44 | 1.5 |

| 200*200*15mm | 25 | 1.4 |

| 200*200*20mm | 25 | 1.8 |

| 200*200*30mm | 25 | 2.7 |

| 300*300*15mm | 11 | 3 |

| 300*300*20mm | 11 | 4 |

| 300*300*30mm | 10 | 6 |

| 230*113*15mm | 38 | 0.9 |

| 230*113*20mm | 38 | 1.2 |

| 230*113*30mm | 38 | 1.8 |

| 230*113*40mm | 38 | 2.5 |

| 230*113*65mm | 38 | 4 |

Acid resistant ceramic tile application:

1.Acid resistant ceramic tile with very excellent acid/alkali resistance, high temperature resistance, and they can withstand violent heat and cold. We also have heat & acids resistant grade.

2.Acid resistant ceramic tile is used as flooringlining in many kinds of industries concerning sulfuric acid, such as,chemical fertilizer industry,papermaking industry,sugar production,brewage production and so on.

Installation of acid resistant ceramic tile :

Using oxalic acid to wash the surface of concrete and tiles, make it neutralization of acid and alkali.

Usually, we use colophony, araldite, acid-proof cement to install the tiles.

The slot between the tiles is usually 8 -10mm . It’s better to make the slot thickness is same as the thickness as the tile thickness to prevent from chemical leakage.

Using the oxalic acid to wash the surface of the floor after the installation.

Packaging and Shipping of our Acid Resistant Bricks

Acid Resistant Bricks, also as well as our Furnace Refractory Bricks are carefully packaged and shipped to ensure safe delivery to our customers. Each step of the packaging and shipping process is closely monitored to maintain the quality and integrity of our products.

Packaging

Our Furnace Refractory Bricks are first wrapped in protective material to prevent any damage during transportation. They are then placed in durable wooden crates or pallets to provide additional protection and stability.

Shipping

We offer various shipping options to meet the specific needs of our customers. Depending on the size and weight of the order, we use different modes of transportation including air, sea, and land. Our experienced logistics team ensures timely and efficient delivery of our products to any destination around the world.

For international shipments, we carefully follow all customs regulations and provide all necessary documentation to facilitate a smooth delivery process.

Our goal is to deliver our Furnace Refractory Bricks to our customers in the best condition and in a timely manner. We strive to maintain the highest standards of packaging and shipping to ensure customer satisfaction.