Application of Magnesia-Carbon Bricks in the Steel And Metallurgy Industry

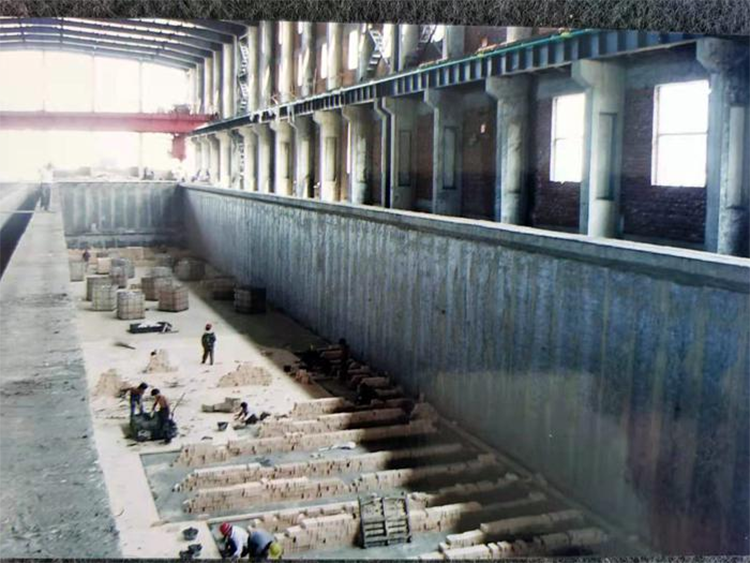

Use of MgO-C Bricks in Refining Ladles and Steel Ladles MgO-C bricks are widely used in refining ladles and steel ladles, primarily in the freeboard and slag line areas. These areas require refractory materials with high resistance to high temperatures, thermal shock, and slag erosion. Traditionally, magnesia-chrome refractories were used for these sections, but due to environmental concerns over chromium pollution, they have been largely replaced by magnesia-carbon bricks. During the preheating process, the MgO-C bricks in new ladles undergo…