Top Benefits of Using Ceramic Fiber Insulation Blankets

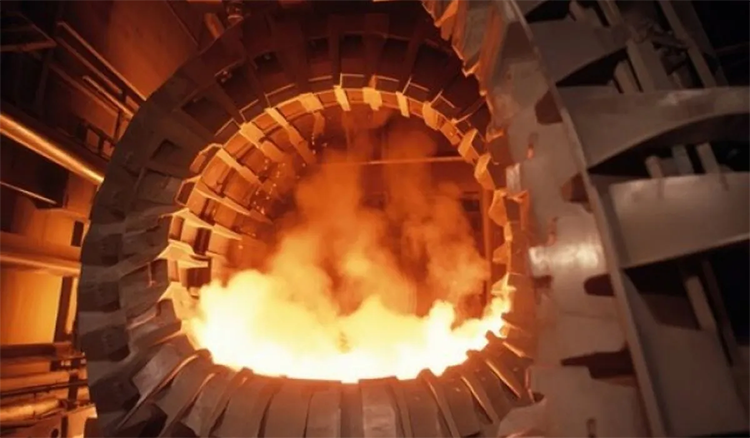

Introduction Ceramic fiber insulation blankets are a versatile solution for thermal management in various industrial sectors. Their ability to provide excellent thermal insulation while being lightweight and easy to handle makes them a preferred choice for many applications. Advantages of Ceramic Fiber Insulation Blankets Ceramic fiber insulation blankets are crafted from high-purity alumina-silicate fibers, offering unparalleled benefits for high-temperature applications. 1. Exceptional Thermal Insulation Ceramic fiber insulation blankets provide outstanding thermal insulation, which is crucial for reducing heat loss and…