Brief Introduction of Electric Arc Furnace

The Electric Arc Furnace (EAF) is an essential tool for the re-processing of steel scrap, helping reduce the steel industry’s carbon footprint. This extremely aggressive process requires a large quantity of high quality refractories.

Refractory Bricks and Monolithics Refractories from Rongsheng Refractory are manufactured using carefully selected raw materials and stringently controlled processes in order to ensure resistance, quality and safety.

Best quality Refractories For Electric Arc Furnace

Several well-known steel producers use Rongsheng Refractory products for the lining of their electric arc furnaces.

After many years of experience Rongsheng Refractory bricks (high-purity fused magnesia products) have proved their efficiency and competitiveness on the market, increasing ladle and furnace lifetime and obtaining a considerable reduction in costs. Top-quality tapping systems and high-performance refractory masses complete our product range.

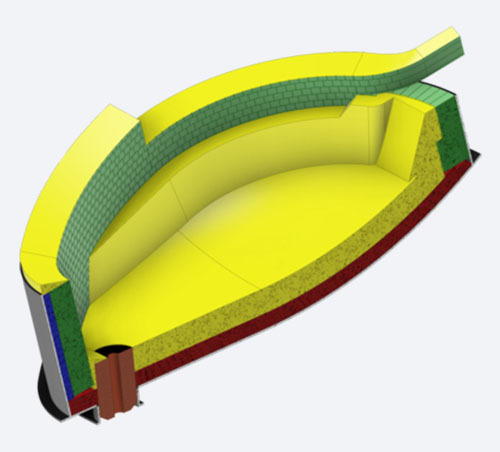

Refractory Selection for Electric Arc Furnace (EAF)

Selection of refractory is the most critical case for building Electric Arc Furnace (EAF) because furnace lifetime depends directly on refractory quality.

1.Side Wall

Sintered Magnesia Brick

Fused Magnesia Brick

2.Safety Lining

Sintered Magnesia Brick

Fused Magnesia Brick

3.Lower Part

Sintered Magnesia Brick

Fused Magnesia Brick

4.Door Zone

Sintered Magnesia Brick

Fused Magnesia Brick

5.Wear Lining

Sintered Magnesia Brick

Fused Magnesia Brick

6.Hot Spot

Sintered Magnesia Brick

Fused Magnesia Brick

7.Hearth

Refractory Castable

8.Cold Repair

Refractory Gunning

9.Hot Repair

Refractory Gunning