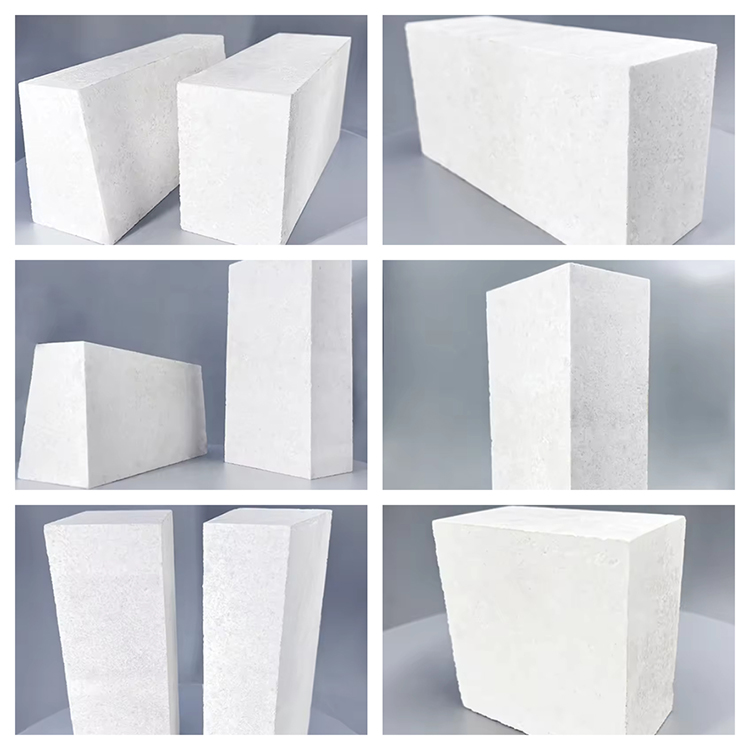

Description of Corundum Bricks:

Corundum brick has high refractoriness under load, good chemical stability, strong resistance to acidic or alkaline slag, metal and glass liquid, etc., and has a dense structure. Corundum bricks are widely applied in extremely high temperature environment, such as pyrolyzer or reformer in petrochemical industry and chemical fertilizer industry, or all kinds of high temperature furnace lining and kiln furniture in metallurgical industry. The corundum bricks we produce have a high bulk density, fine compressive strength and can serve under high temperature above 1790℃.

Features of Corundum Fire Bricks

* High temperature resistance;

* High compression strength;

* High dense structure;

* Good thermal shock resistance;

* Strong resistance to acid and alkaline slag erosion;

* Good chemical stability;

* Good resistance to metal and glass liquid;

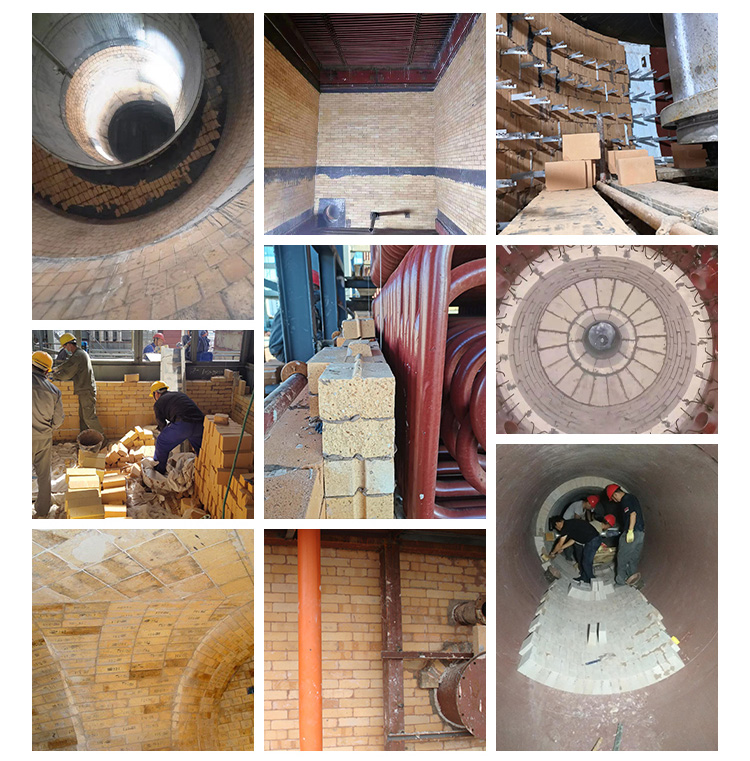

Application of Corundum Bricks:

Blast Furnace And Hot Air Stove For Blast Furnace

Refining Furnace for Steelmaking Furnace

Sliding Water Heater

Glass Melting Furnace

Petrochemical Industrial Furnace.

High-Temperature Tunnel Kiln

Down-Draft Kiln

Parameter of Corundum Bricks:

| Item | Index | ||||

| GYZ-99A | GYZ-99B | GYZ-98 | GYZ-95 | ||

| Al2O3 % | ≥99 | ≥99 | ≥98 | ≥95 | |

| SiO2 % | ≤0.15 | ≤0.2 | ≤0.5 | / | |

| Fe2O3 % | ≤0.1 | ≤0.15 | ≤0.2 | ≤0.3 | |

| Apparent Porosity % | ≤19 | ≤19 | ≤19 | ≤20 | |

| Bulk Density g/Cm3 | ≥3.20 | ≥3.15 | ≥3.15 | ≥3.1 | |

| Cold Crushing Strength Mpa | ≥80 | ≥80 | ≥80 | ≥100 | |

| 0.2Mpa Refractoriness Under Load ℃ | ≥1700 | ||||

| Permanent Linear Change Rate % 1500℃×2h | ±0.2 | ±0.3 | |||

High Purity Corundum Brick

High-purity corundum bricks are mainly made of high-purity raw materials and ultra-fine powder through high-pressure forming and high-temperature sintering. They are mainly used in key parts of kilns in steel, petrochemical, non-ferrous, electronics and other industries. They have high temperature resistance, high strength, corrosion resistance and erosion resistance. and other excellent features.

| Item | Index |

| Al2O3 % | ≥99 |

| SiO2 % | ≤0.15 |

| Fe2O3 % | ≤0.12 |

| Bulk Density g/cm3 | ≥3.2 |

| Apparent Porosity % | ≤16 |

| Cold Crushing Strength MPa | ≥100 |

| 0.2Mpa Refractoriness Under Load ℃ | ≥1700 |

| Permanent Linear Change Rate % 1600℃×3h | ±0.2 |

| Thermal shock resistance cycle 1100℃water cooling | ≥5 |

About Rongsheng Refractory Factory

As professional refractory material supplier and manufacturer, Rongsheng Refractory Factory is located in Xinmi city, the “Capital of Refractory” in China. We specialize in refractory products for nearly 15 years, covering a full range of shaped and unshaped refractory products, such as High Alumina Series Bricks, Mullite Bricks, Corundum Series Bricks, Silica Series Bricks, Andalusite Bricks, Magnesia Series Brick, Carborundum Brick, Insulating Series Brick, Insulating and Dense Castables, also other related products for more sophisticated applications.

Packing & Shipping

Every possible precaution is taken to ensure our products in prime condition when reach customers around the world.By sea or air. Normally 7 to 14 Days for delivery, according to your order quantity.

Engineering Case

Why choose us?

1.Abundant Experience. Rongsheng Group have over 20 years experience in the refractory industry and we have a deep understanding of the materials and applications we work with. We can provide expert advice and guidance to help customers find the best solutions for their needs.

2.Quality products. We pride ourselves on providing high-quality refractory products that are made to last. Our materials are carefully sourced and tested to ensure they meet our strict standards.

3.Competitive Price. We offer competitive pricie on all of our products without sacrificing quality and make the products competitive in your market.

4.Customization. We understand that every customer is unique, which is why we offer customized solutions tailored to their specific requirements. Whether it’s a custom shape or size, we can work with customers to create the ideal product for their application.

5.Safety. We take safety seriously and ensure that all of our products meet safety standards. Safty packing, prompt delivery time, and excellent after-sales services.

6.Large stocks. With a large stock of products on hand, we can better serve our customers, save money, and gain a competitive edge in their industry.

7. Overall solutions. We offer optimal and comprehensive solutions to supply the necessary refractory material for your high temperature kiln.

8.Long-term relationships. We believe in building long-term relationships with our customers based on trust and mutual benefit. We are committed to providing ongoing support and service to ensure customer satisfaction. Rongsheng Refractory can be used in many fields of steel, nonferrous metals, glass, cement, ceramic, petrochemical, machinery, boiler, light, and power industries. What’s more, Industrial distributors, refractory contractors, sales agents, trading companies, and refractory consultants can all benefit from promoting and selling our top-of-the-line refractory products. With a focus on durability, longevity, and performance, our products are designed to exceed your expectations and provide your customers with the best possible results.

So choosing us is the right choice for you.If you are interested in our products or if you have any question, pls feel free to contact us at any time. We will reply as soon as possible.