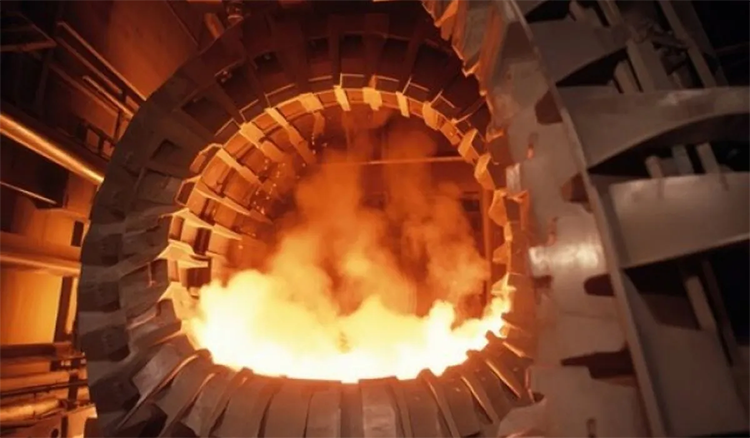

High-Performance Taphole Clay For Blast Furnaces

High-Performance Taphole Clay for Blast Furnaces As modern blast furnace ironmaking becomes increasingly large-scale and intensive, the demands on taphole clay performance continue to rise. Frequent tapping, longer tapping durations, and higher iron output volumes challenge the refractory materials sealing the taphole. For steelmakers, selecting high-quality taphole clay is crucial to maintain safe, efficient, and stable operations. The Importance of Reliable Taphole Clay In large blast furnaces—especially those with volumes over 4000m³—the taphole can be tapped more than 10 times…