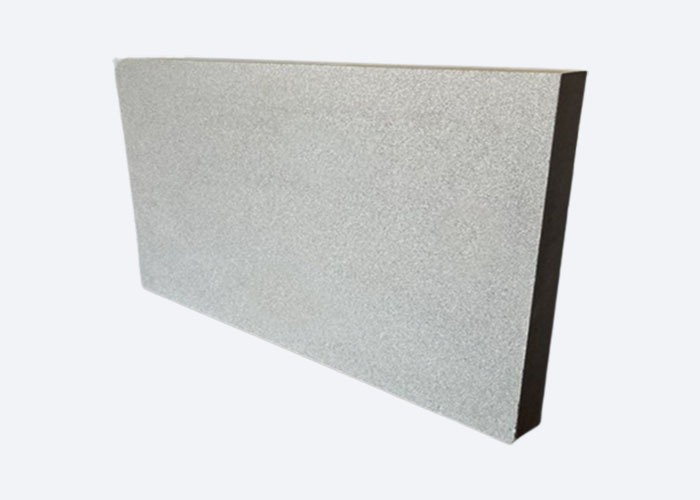

Description of Inorganic Insulation Board

The inorganic insulation series product is a new type of refractory insulation material made from pure inorganic materials processed through a large-scale automated continuous production line. It can be used in various industrial kiln backings, with a temperature range of 900°C to 1300°C, effectively addressing the insulation and thermal insulation issues of kilns. It can be processed and produced with bulk densities ranging from 0.35 to 0.5. It fills a gap in the domestic market, with thermal conductivity controlled within the range of 0.11 to 0.13 at 350°C and strength controlled within the range of 1 to 2 MPa. It can be processed into various shapes, with the maximum size being 1 meter by 2 meters.

Features of Inorganic Insulation Board

(1)Main Features

A)Low thermal conductivity, more energy saving. The composition structure has nano-micro porosity, which makes the product have good thermal insulation performance.

B)No shrinkage and small gap after heating. The permanent linear change rate after heating does not exceed 0.5% within the specified working temperature, and does not shrink in long-term use. The heating permanent line change rate of ordinary insulation board reaches 2%-3%, and the shrinkage is more than 4 times that of inorganic insulation board.

C)Completely fiber-free, organic-free, all inorganic materials, no chalking and no performance degradation with long-term.

D)High strength and wide range of use.Compared with ordinary thermal insulation board, it has better cold crusing strength, which is more than 3 times, and also has good strength after burning. It can be used in high temperature for a long time, which is safer and wider range of use.

E)No stimulation to human body, no pollution to the environment, convenient, healthy and eco-friendly.

F)Good quality control, high capacity, no environmental policy restrictions and guaranteed delivery time.

Typical Applications

Application: It can be used for back lining insulation of furnaces, including heat treatment furnace in metallurgical industry, roller kiln in ceramic industry, decomposition furnace in cement industry, electrolytic tank in electrolytic furnace in aluminum industry, cracking furnace in chemical industry.

A)Backing Plate of Roller Kiln in Ceramic Industry

Application: Ceramic roller kiln wall insulation backing plate, bottom backing insulation.

Alternative of following: 1260 aluminium silicate fiber board. 1400 aluminium silicate fibre board.

Advantage: less shrinkage, less chalking, less decay of performance and higher cost performance.

Parameters of Inorganic Insulation Board

| Casification Model | RS-B 0.35 | RS-B 0.55 | RS-B 0.6 |

| BD.g/cm’ | ≤ 0.35 | ≤ 0.55 | ≤ 0.6 |

| CCS.MPa | ≥0.8 | ≥2.0 | ≥2.0 |

| 400°C, TC,W/(m.K) | ≤0.105 | ≤0.115 | ≤0.12 |

| PLC, % | 土0.5 950°Cx 12h | 土0.5 1250°CX12h | 土0.5 1250°CX12h |

Why choose us?

1.Abundant Experience. Rongsheng Group have over 20 years experience in the refractory industry and we have a deep understanding of the materials and applications we work with. We can provide expert advice and guidance to help customers find the best solutions for their needs.

2.Quality products. We pride ourselves on providing high-quality refractory products that are made to last. Our materials are carefully sourced and tested to ensure they meet our strict standards.

3.Competitive Price. We offer competitive pricie on all of our products without sacrificing quality and make the products competitive in your market.

4.Customization. We understand that every customer is unique, which is why we offer customized solutions tailored to their specific requirements. Whether it’s a custom shape or size, we can work with customers to create the ideal product for their application.

5.Safety. We take safety seriously and ensure that all of our products meet safety standards. Safty packing, prompt delivery time, and excellent after-sales services.

6.Large stocks. With a large stock of products on hand, we can better serve our customers, save money, and gain a competitive edge in their industry.

7. Overall solutions. We offer optimal and comprehensive solutions to supply the necessary refractory material for your high temperature kiln.

8.Long-term relationships. We believe in building long-term relationships with our customers based on trust and mutual benefit. We are committed to providing ongoing support and service to ensure customer satisfaction. Rongsheng Refractory can be used in many fields of steel, nonferrous metals, glass, cement, ceramic, petrochemical, machinery, boiler, light, and power industries. What’s more, Industrial distributors, refractory contractors, sales agents, trading companies, and refractory consultants can all benefit from promoting and selling our top-of-the-line refractory products. With a focus on durability, longevity, and performance, our products are designed to exceed your expectations and provide your customers with the best possible results.

So choosing us is the right choice for you.If you are interested in our products or if you have any question, pls feel free to contact us at any time. We will reply as soon as possible.