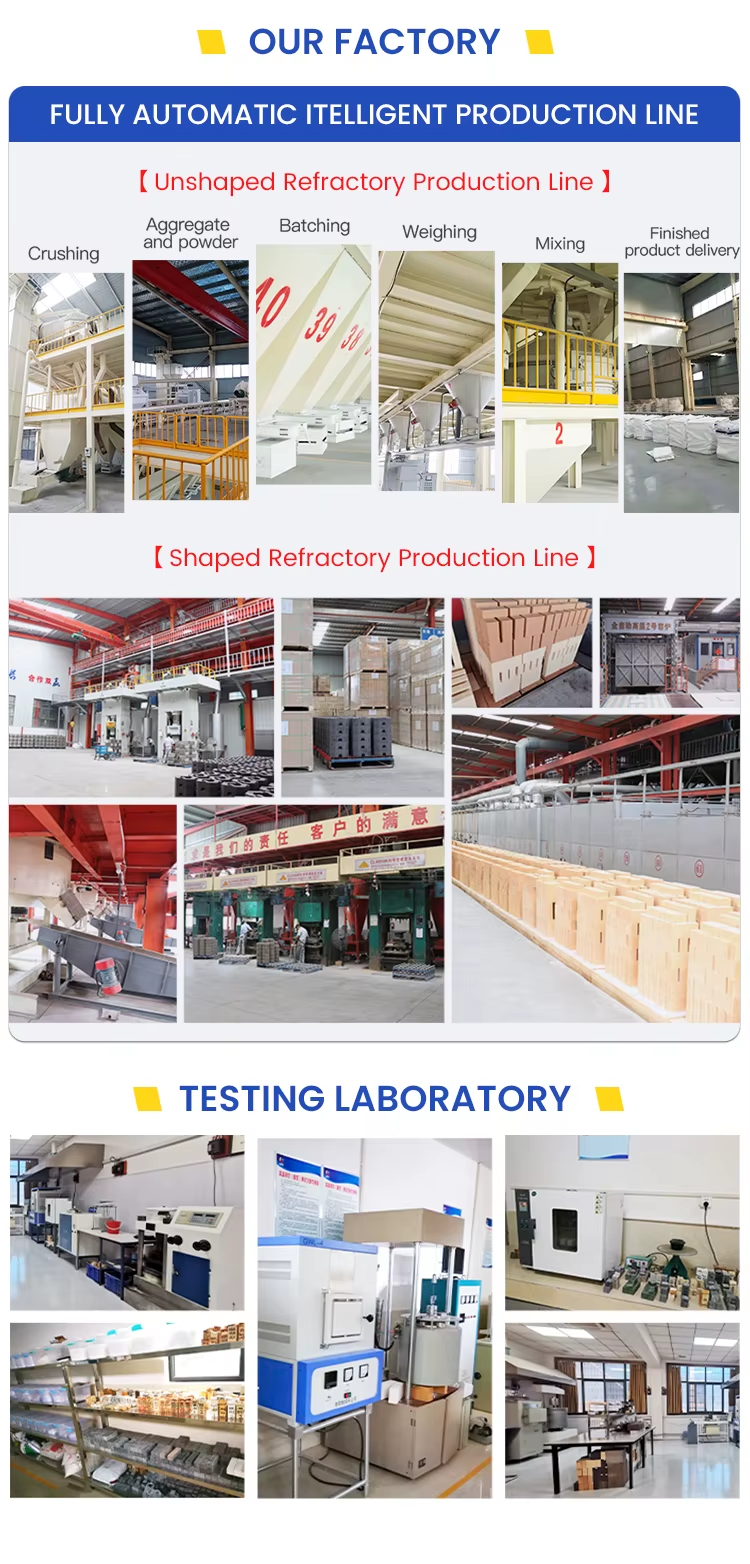

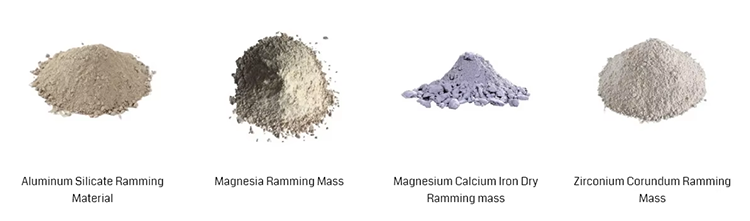

Product Description of High Quality Hot Sale Aluminum Silicate Ramming Material With Factory Price

Rongsheng Refractory Aluminum silicate ramming material is made of pure raw materials with low iron and low impurity content through reasonable grading and high efficiency admixture. It has high fire resistance, good abrasion resistance, strong thermal shock resistance, strong corrosion resistance and other excellent characteristics. It can be divided into different materials according to the raw materials used.

Features of High Quality Aluminum Silicate Ramming Material Rongsheng Factory Direct Supply

1.On the face in contact with liquid metal there is a dense sintered layer where tightness of liquid metal is quite perfect.

2.Thermal conductivity is lower than other refractoriness so the Thermal loses are less than any other kind of refractory.

3.Good resistance to temperature change.

4.Low cost in furnace lining.

5.Short heating and sintering time through dry preparation Of masses.

6. Strong resistance to erosion.

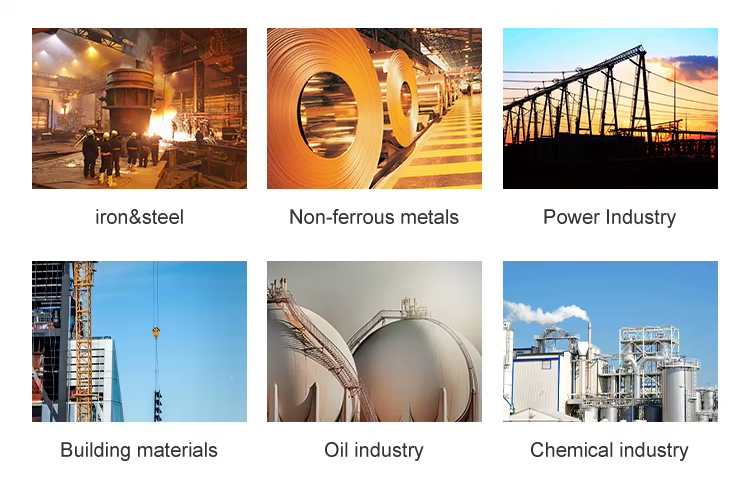

Product Applications of Rongsheng Hot Sale Fireproof Aluminum Silicate Ramming Material

Rongsheng Refractory Ramming Mass are mainly used for furnace lining of boiler, blast furnace, hot blast stove, heating furnace, ceramic kiln and various industrial furnaces.Applicable to all kinds of carbon steel, low manganese steel, alloy steel, alloy cast iron, high-speed tool steel and stainless steel.

Product Specificaton of Aluminum Silicate Ramming Material With Factory Price

| Item | Alumina-Silicon | Silicon- Carbide | Zirconium Chrome Corundum | ||||

| KSL-1 | KSL- | KSL- | KSL- | KSL- | KSL- | KSL- | |

| Al2O3 % | ≥65 | ≥75 | ≥85 | / | / | / | ≥80 |

| SiC % | / | / | / | ≥40 | ≥60 | ≥70 | / |

| Cr2O3 % | / | / | / | / | / | / | ≥3 |

| ZrO2 % | / | / | / | / | / | / | ≥2 |

| Bulk Density g/cm3 110℃×24h | ≥2.5 | ≥2.7 | ≥2.8 | ≥2.4 | ≥2.5 | ≥2.6 | ≥2.8 |

| Permanent Linear Change Rate % 1000℃×3h | -0.4~0 | -0.5~0 | -0.5~0 | -0.4~0 | -0.5~0 | -0.6~0 | -0.6~0 |

| Cold Crushing strength MPa 1000℃×3h |

≥70 | ≥80 | ≥90 | ≥60 | ≥70 | ≥80 | ≥90 |

| Wear resistance at room temperature cm3 1000℃×3h | ≤7 | ≤6 | ≤5 | ≤7 | ≤6 | ≤5 | ≤5 |

| Thermal shock resistance 1000℃ water cooling cycle 1000℃×3h Fired | ≥30 | ≥30 | ≥25 | ≥30 | ≥35 | ≥40 | ≥30 |

| Plasticity Index % | 15~55 | ||||||

| Thermal conductivity W/(m·K) 1000℃ | 1.1~1.6 | 1.6~2.0 | 3~5 | 5~7 | 6~8 | 2~3 | |