Product Description Magnesia Ramming Mass For Induction Furnaces

Ramming mass is composed of refractory aggregate, powder, binder, additives, etc. in proportion. The amount of powder used in the ramming mass is large, while the amount of binder is small. Due to the use of ramming methods for construction, it is called refractory ramming mass.Ramming mass into acid, neutral, alkaline three.

Magnesia ramming mass is an alkaline unshaped refractory made of high-purity fused magnesia/sintered magnesia with ultra-fine powder and additives. It has the characteristics of corrosion resistance, erosion resistance, good volume stability, high load softening temperature and convenient construction. It is mainly used for new lining, repair and caulking of iron and steel metallurgy furnace.

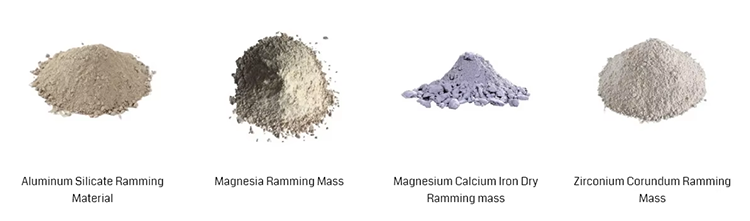

Product Classification of Refractory Ramming Mass Material

According to material classification, there are high alumina, clay, magnesium, dolomite, zirconium, and silicon carbide carbon refractory ramming mass.

Product Feature of Magnesia Ramming Mass For Induction Furnaces

1.On the face in contact with liquid metal there is a dense sintered layer where tightness of liquid metal is quite perfect.

2.Thermal conductivity is lower than other refractoriness so the Thermal loses are less than any other kind of refractory.

3.Good resistance to temperature change.

4.Low cost in furnace lining.

5.Short heating and sintering time through dry preparation Of masses.

6. Strong resistance to erosion.

Product Application of Magnesia Ramming Mass

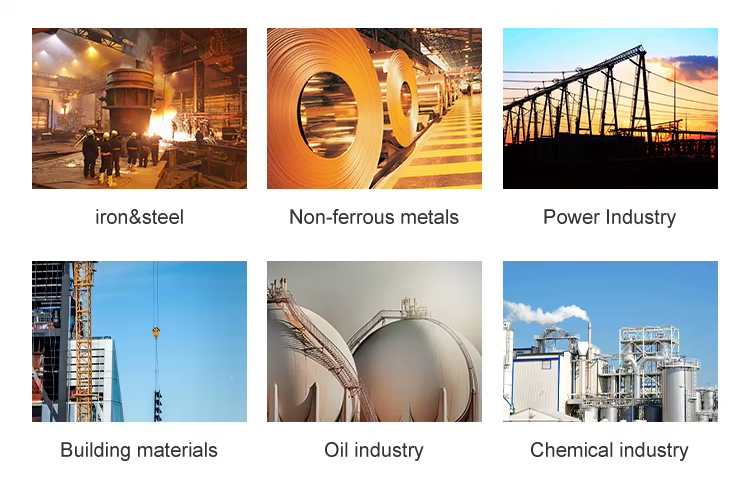

It is mainly used for lining various industrial furnaces such as boilers, blast furnace iron trenches, converters, ferroalloy electric furnaces, open hearth furnaces, intermediate frequency furnaces, power frequency furnaces, tundishes, electric furnaces, rotary kiln discharge ports, hot blast furnaces, heating furnaces, ceramic kilns, and various non ferrous metal smelting furnaces such as copper, aluminum, and steel.

Advantage of Rongsheng Refractory Magnesia Ramming Mass

1.Accurate composition: Our refractory refractory ramming mass are known for their accurate composition, ensuring reliable performance, safety, meeting international standards, and no side effects, with eco-friendly formulations.

2.High quality: Strict quality control and more than 20 years experiences. We are committed to delivering high-quality solutions trusted by industries worldwide.

3. Competitive price: Directly from our factory to your hands without other traders.

4. Good packaging: Avoid damage and secure your goods in transportation.

4. Quick response: Your any questions will be replied within 24 hours.

5. Professional technology: The size, density, chemical composition can be customized.

6. Geographical advantage: Our factory is located in Henan province, which is one of the main refractory production bases in China. we have abundant resources and high quality minerals. This favorable condition reduce the cost to save you money.

7. Timely delivery: 10-20 days after receiving deposit.

8. Samples are free.

Product Parameters of Magnesia Ramming Mass:

| Item | Index | |

| MZD1 | MZD2 | |

| MgO % | ≥90 | ≥95 |

| Cr2O3 % | ≥2 | |

| Bulk Density g/cm3 110℃×24h | ≥2.8 | ≥2.85 |

| Cold Crush Strength MPa 110℃×24h | ≥30 | ≥40 |

| Grain Size mm | 0~5 | |

| Bonding Type | Chemical ceramic bonding | |

Product Packaging of Magnesia Ramming Mass

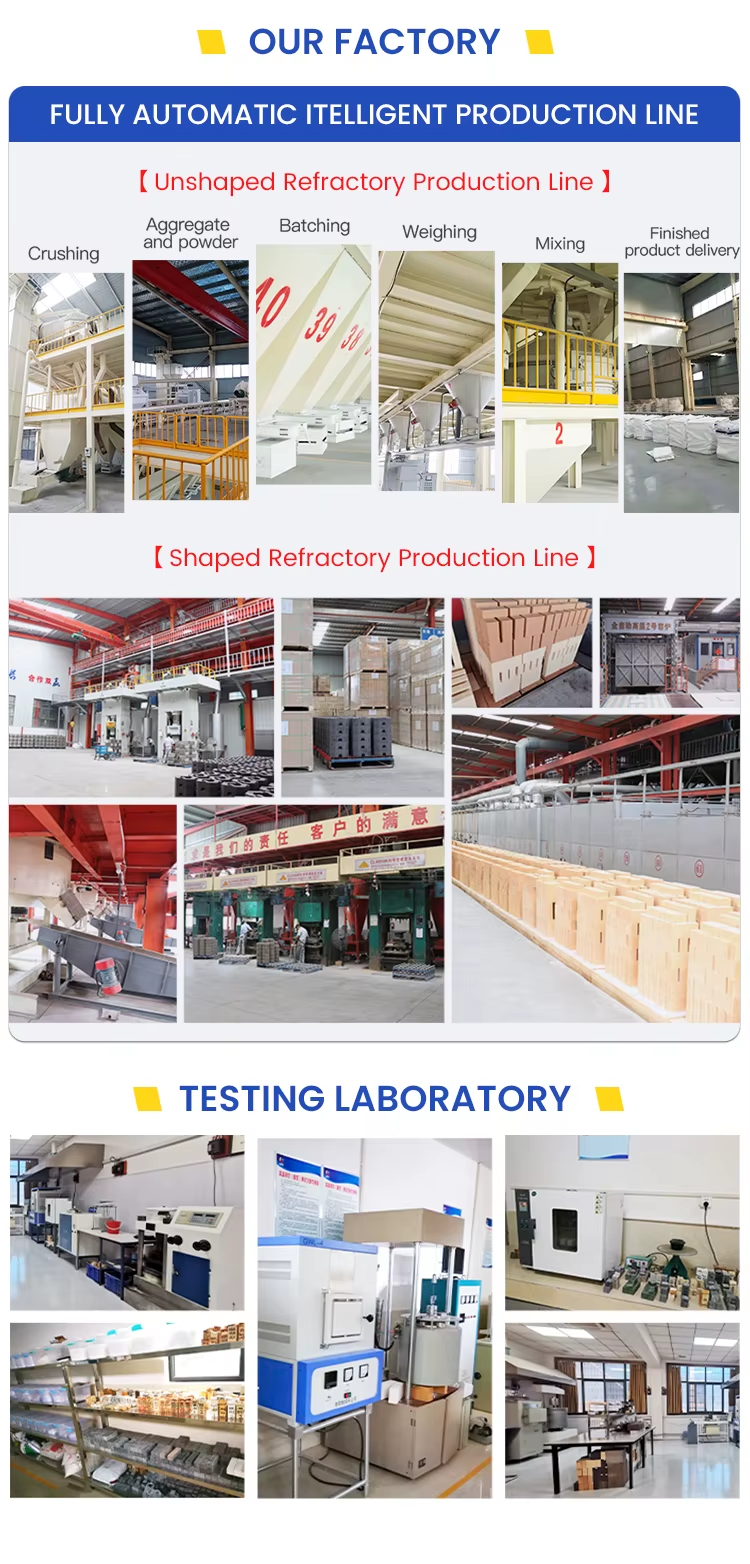

Company Profile of Rongsheng Magnesia Ramming Mass Manufacturer And Supplier

Henan Rongsheng Xinwei New Materials Research Institute Co., Ltd., headquartered in Zhengzhou City, Henan Province, is affiliated to Henan Rongsheng Technology Group. Rongsheng Refractory have been the Leading manufacturer, Supplier & Exporter of top-quality refractory materials for more than 20 years. Our product range includes high alumina bricks, corundum bricks, azs bricks, magnesia bricks, fire clay bricks, insulating bricks, and unshaped materials such as refractoy castable, refractory cement, refractory motar, refractory ramming mass, refractory Spraying Mass, Refractory Plastic, etc. Our diverse product range caters to 90% of the refractory needs in industries like Iron & Steel Industry, Cement Industry, Non-ferrous Industry, Power Industry, Petrochemical Industry and Glass Industry. And our products are exported to more than 100 countries and regions all over the world. We are renowned as one of the top refractory brick supplier and refractory material supplier in the industry.