Product Descripton of Rongsheng High Temperature High Quality Low Cement Castable For Kiln

The refractory product range includes low cement castable of different Alumina content (Al2O3 varying from 45% to 90%) with service range between 1450 °C to 1800 °C. These are characterized by Al2O3 content and specific low Fe2O3 and low CaO content. Also water requirement for casting is less than 5%. These castables have very short curing time requirement. These are suitable for use in places where very quick setting is required thus reducing the downtime of Furnaces.

Rongsheng Refractory have been the Leading manufacturer, Supplier & Exporter of top-quality shaped and unshaped refractory materials for more than 20 years. Our Low and ultra-low Cement Castables mainly includes three types: high alumina refractory castable, clay refractory castable, corundum refractory castable. They have the characteristics of small pore size, large density, good volume stability, high strength and small amount of water. They overcome the characteristics that the strength of ordinary castables decreases significantly at 800~1200 ℃, increase with the increase of temperature, and have excellent thermal shock resistance, slag resistance and corrosion resistance. The Low and ultra-low Cement Castables are high quality, competitive price, fast delivery and direct supply by manufacturer.

1.High refractoriness, high temperature strength and slag resistance.

2.Low porosity & High bulk density.

3.Low water content.

4.High strength.

5.High thermostability.

High Alumina Low Cement Castable is developed based on refractory castable bonding clay, which has the varieties of low cement castable, ultra low cement castableb, non-cement or submicron powder and soild binder.

1.High density.

2.Low porosity.

3.High strength.

4.Low abrasion.

5.Thermal shock resistance.

6.Resistance to erosion.

7.Good using effect.

Low cement and ultra low cement castable’s service temperature is higher than the same materials common refractory castable.

1.Low cement castables are used for linings of iron runner for blast furnace, iron notch for iron-melting furnace, pretreatment of hot metal monolithic powder gun.

2.Clay and high alumina low cement castable can be used for all kinds of thermal treatment furnace of heating furnace and soaking pit and rotary kiln linings.

3.Corundum and Zirconia-corundum low cement castable refractory material can be used for pats’ linings of molten steel furnace refining device.

4.Mullite low cement catable can be used for linings of high temperature nozzle and water-cooled tube binding lings of heating furnace.

Physical And Chemical Parameter of Rongsheng Low And Ultra Low Cement Castable Refractory

| Item | Index | |||

| Clay | High Alumina | Corundum | ||

| Al2O3 % | ≥45 | ≥75 | ≥98 | |

| CaO % | <1.8 | <1.5 | <1.0 | |

| Bulk density g/cm3 | 110℃×24h | ≥2.3 | ≥2.6 | ≥3.1 |

| 1350℃×3h | ≥2.26 | ≥2.61 | / | |

| 1550℃×3h | / | / | ≥3.00 | |

| Cold Crushing Strength MPa | 110℃×24h | ≥70 | ≥75 | ≥85 |

| 1350℃×3h | ≥85 | ≥90 | / | |

| 1550℃×3h | / | / | ≥100 | |

| Flexural Strength MPa | 110℃×24h | ≥6 | ≥8 | ≥9 |

| 1350℃×3h | ≥8 | ≥9 | / | |

| 1550℃×3h | / | / | ≥11 | |

| Permanent linear change Rate % | 1000℃×3h | -0.3 | -0.2 | -0.2 |

| 1350℃×3h | ±0.3 | ±0.5 | / | |

| 1550℃×3h | / | / | ±0.5 | |

| Maximum service temperature ℃ | 1450 | 1600 | 1800 | |

Packaging & Shipping

About Us

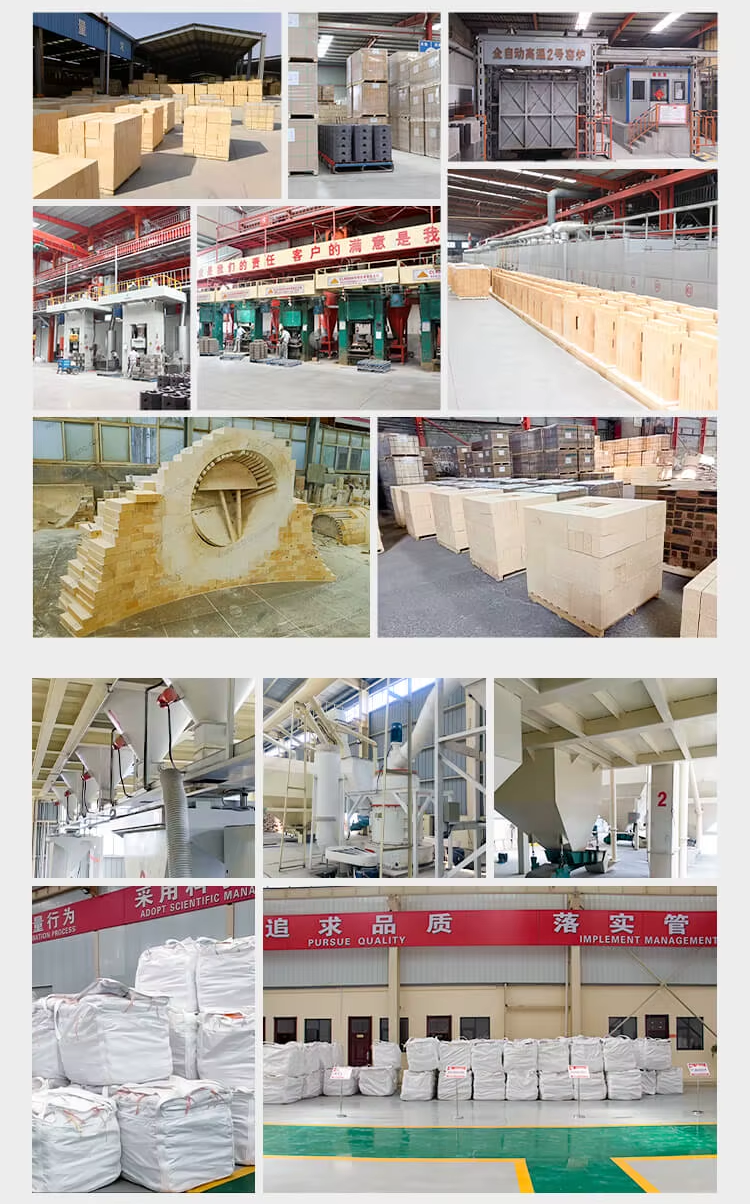

Rongsheng Refractory have been the Leading manufacturer, Supplier & Exporter of top-quality refractory materials for more than 20 years. Our product range includes high alumina bricks, corundum bricks, azs bricks, magnesia bricks, fire clay bricks, insulating bricks, and unshaped materials such as refractoy castable, refractory cement, refractory motar, refractory ramming mass, refractory Spraying Mass, Refractory Plastic, etc. Our diverse product range caters to 90% of the refractory needs in industries like Iron & Steel Industry, Cement Industry, Non-ferrous Industry, Power Industry, Petrochemical Industry and Glass Industry. And our products are exported to more than 100 countries and regions all over the world. We are renowned as one of the top refractory brick supplier and refractory material supplier in the industry.

Rongsheng Refractory Factory

Rongsheng Refractory has established complete quality system and conducted quality control through the whole staff and process that from raw materials, production, check and various parts strictly according to ISO9001 standard.Annual production capacity is up to 60000 tons. There are light and heavy weight materials production lines and all kinds of complete production, testing and check equipment, of which there are 10 series shaped press machine that from 400 tons to 1000 tons and two hyperthermia tunnel kilns whose length are 148m and 118m.

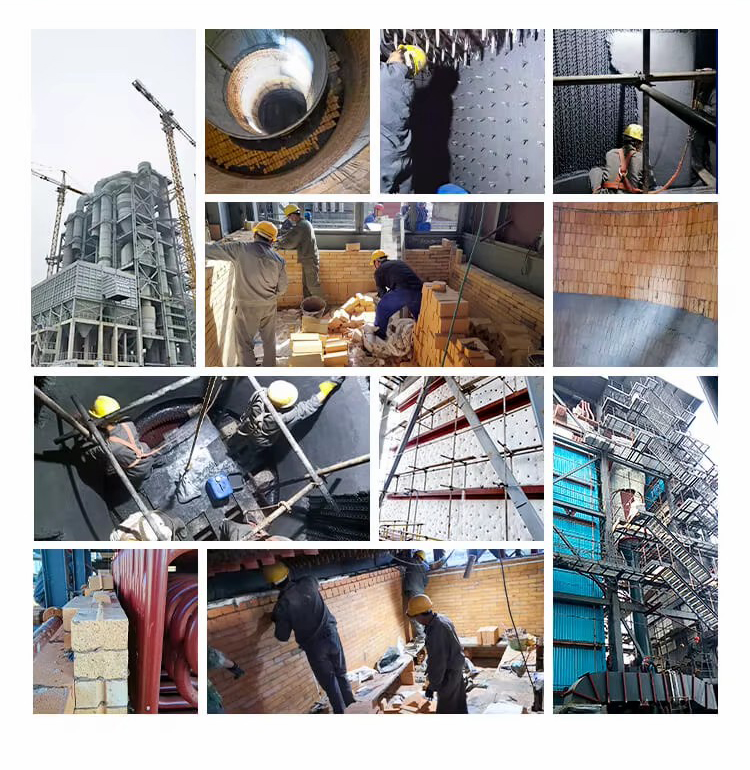

Rongsheng holds the third-level qualification certificate of metallurgical general contracting for furnace construction, the second-level anti-corrosion insulation qualification certificate, the quality management system ISO 9001 certification, 14001 certification, 45001 certification, 18001 certification and AAA-level credit enterprise certification. 25 Years of experience, more than 2,000 furnace cases around the world, and a team that can execute more than 20 furnace construction projects at the same time.

Contact Us

If you want to know more about the product details, Please conact us right now.