Description of Slide Gate Plate Refractories For Tundish And Ladle:

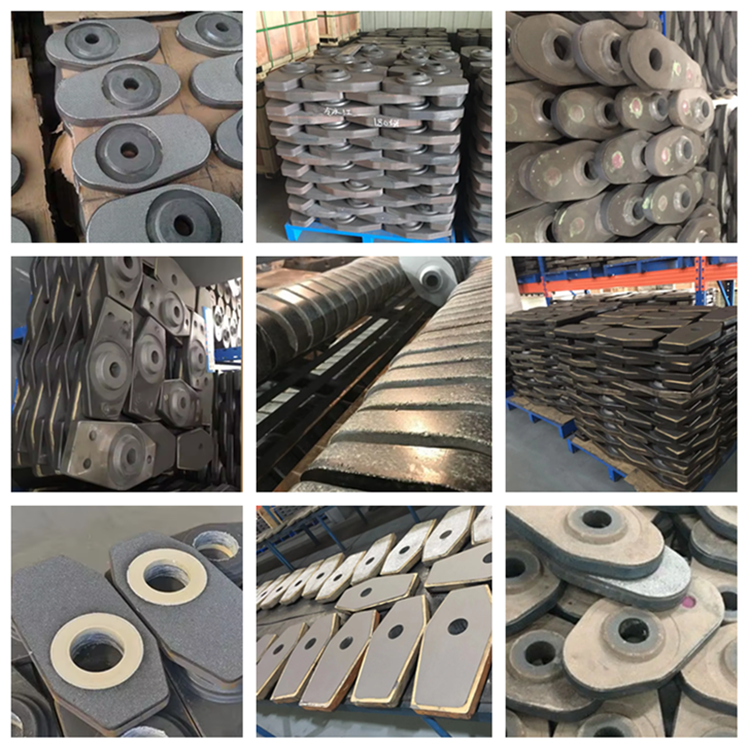

The main raw materials of slide gate plate refractories are aluminum carbon and aluminum zirconium carbon. The need of special steel makes the development of slide plate diversified. Slide gate plates are also called sliding gate brick. The sliding plate brick has the advantages of high fire resistance, good chemical stability, slag and liquid metal corrosion resistance, good oxidation resistance and spalling resistance. Rongsheng Refractory supply a range of high quality of refractory slide gate plate,which including ladle slide plate, tundish slide plate, ladle & collector nozzle, tundish nozzle, submerged entry nozzle, etc widely used in steel and iron industry.

slide gate plate becomes more and more important in the process of modern steel smelting, becoming an indispensable part of smelting.It is in the process of continuous casting machine casting steel control device, can accurately adjust the water flow from the ladle in continuous casting tundish, the inflows and outflows of molten steel in balance, so that the continuous casting operation is easier to control.

Product Features of Ladle Slide Gate Plate Refractories

1.High mechanical strength

2.Good thermal shock resistance

3.Good resistance to abrasion and corrosion

4.Good volume stability at high temperature

Product Application of Ladle Slide Gate Plate Refractories

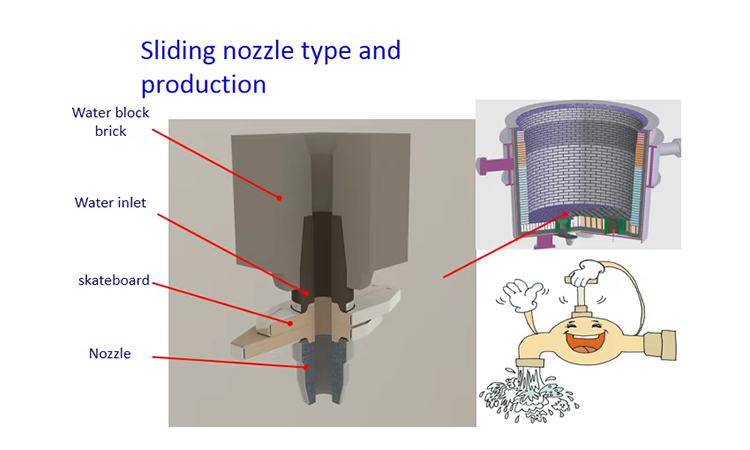

Where is the Sliding Plate Use?

Sliding Plate (SP) is one of the main components of the sliding gate system. According to the number of sliding plates that make up the sliding gate system, it can be divided into two-layer and three-layer types. The sliding plates for the ladle are generally two-layer. During operation, the upper sliding plate is fixed and the lower sliding plate is used to intercept and throttle. The sliding plates for the tundish are generally three-layer. During operation, the upper sliding plate is fixed to the upper gate, the lower sliding plate is fixed to the lower gate, and the middle sliding plate is used to intercept and throttle.

Technical Parameter of Ladle Slide Gate Plate:

Aluminum Carbon Type:

| Item | Index | |||

| HBLT80 | HBLT75 | HBLT70 | ||

| Al2O3 % | ≥80 | ≥75 | ≥70 | |

| C % | ≥2 | ≥3 | ≥3 | |

| Cold Crushing Strength MPa | Non impregnation | ≥80 | ≥70 | ≥60 |

| Impregnation | ≥100 | ≥90 | ≥80 | |

| Apparent porosity % | Non impregnation | ≤13 | ≤13 | ≤13 |

| Impregnation | ≤10 | ≤10 | ≤10 | |

| Bulk density g/cm3 | Non impregnation | ≥2.9 | ≥2.85 | ≥2.75 |

| Impregnation | ≥2.95 | ≥2.9 | ≥2.85 | |

Aluminum Zirconium Carbon Type:

| Item | Index | ||||

| HBLTG80 | HBLTG75 | HBLTG70 | HBMLT80 | ||

| Al2O3 % | ≥80 | ≥75 | ≥70 | / | |

| Al2O3+MgO % | / | / | / | ≥80 | |

| C % | ≥3 | ≥3 | ≥4 | ≥3 | |

| ZrO2 % | ≥4 | ≥4 | ≥4 | / | |

| Apparent porosity % | Non impregnation | ≤13 | ≤13 | ≤13 | ≤13 |

| Impregnation | ≤10 | ≤10 | ≤10 | ≤10 | |

| Bulk density g/cm3 | Non impregnation | ≥3.0 | ≥2.95 | ≥2.9 | ≥2.75 |

| Impregnation | ≥3.05 | ≥3.0 | ≥2.95 | ≥2.8 | |

| Cold Crushing Strength MPa | Non impregnation | ≥90 | ≥90 | ≥80 | ≥70 |

| Impregnation | ≥110 | ≥110 | ≥100 | ≥90 | |

About Rongsheng Refractory

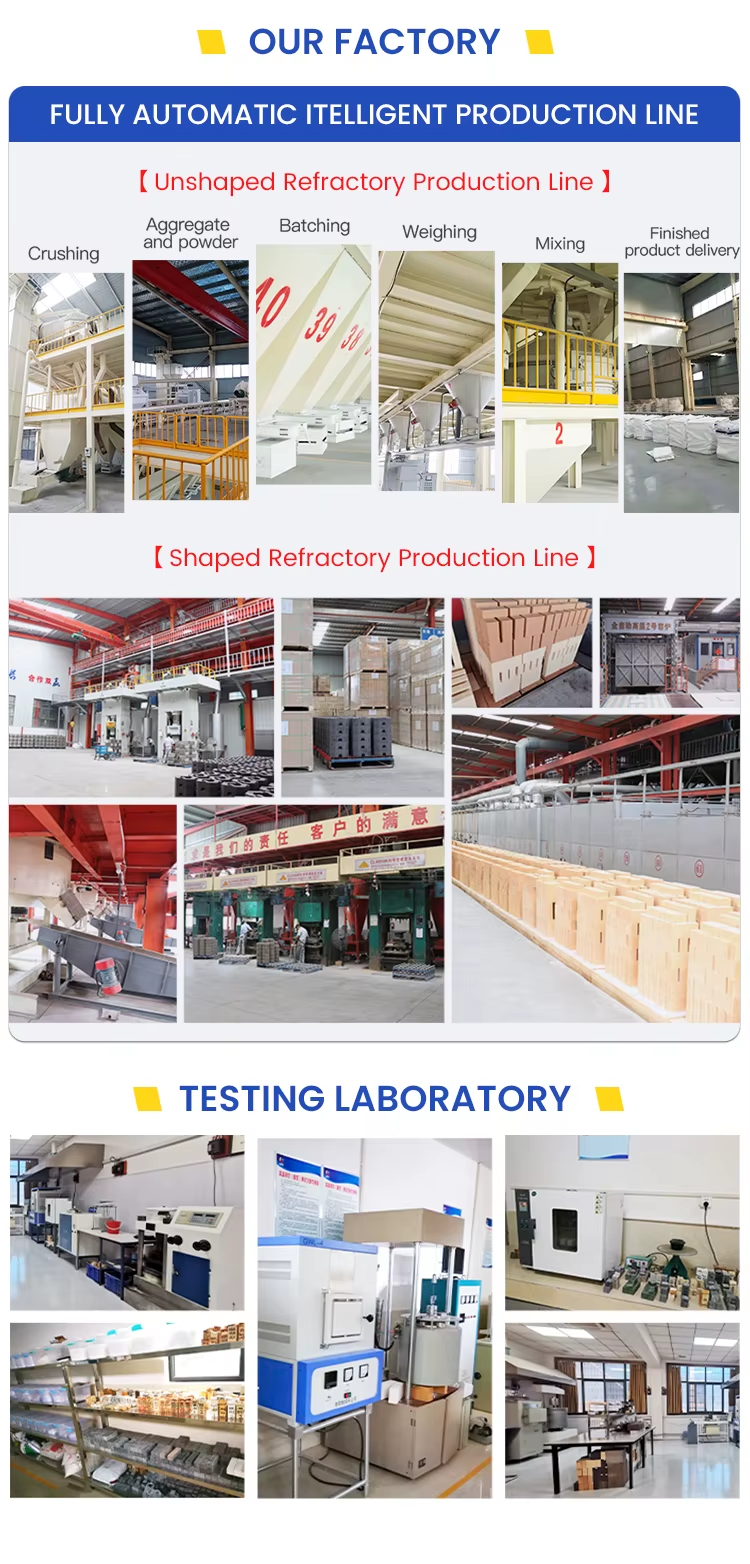

As professional refractory material supplier and manufacturer, Rongsheng Refractory Factory is located in Xinmi city, the “Capital of Refractory” in China. We specialize in refractory products for nearly 20 years, covering a full range of shaped and unshaped refractory products, such as High Alumina Series Bricks, Mullite Bricks, Corundum Series Bricks, Silica Series Bricks, Andalusite Bricks, Magnesia Series Brick, Carborundum Brick, Insulating Series Brick, Insulating and Dense Castables, also other related products for more sophisticated applications. We are recognized as a top fire brick factory and refractory material supplier.

With 280 workers, 20000 square meter workshop, 30 years experience, CE & ISO9001 / 2008 certificated, biggest raw refractory material original area in China, this is how we keep good quality and reliable cooperation for global valued customers. After nearly 30 years of innovation, Rongsheng Refractory has developed into a large-scale group enterprise known as a collection of science, industry and trade all over the world. Cooperate with many universities to establish research and development center, professional customer service and technology continuous tracking, can provide customers with differentiated, serialized, customized refractory products and services.

Believe that you will be the same as the customers which are from more than 100 countries and regions all over the world, and think it is so wise to choose Rongsheng Refractory, Rongsheng is here for you at any time. Welcome your inquiry.

Certificates of Rongsheng Refractory Group

Rongsheng Group holds several international certifications, including ISO9001, ISO14001, OHSAS18001, CE, and SGS. We also have numerous domestic certifications. As a top refractory company and refractory suppliers, we are dedicated to innovation and customer satisfaction. We collaborate with universities to establish research and development centers, providing customers with differentiated, serialized, and customized refractory products and services.

Professional Sales Team

Customer Visit

Join our satisfied customers from over 100 countries and regions who trust Rongsheng Refractory for their needs. As a leading refractory brick manufacturers and refractory material supplier, we are here for you at any time. Welcome your inquiry.

Why choose us?

1.Abundant Experience. Rongsheng Group have over 20 years experience in the refractory industry and we have a deep understanding of the materials and applications we work with. We can provide expert advice and guidance to help customers find the best solutions for their needs.

2.Quality products. We pride ourselves on providing high-quality refractory products that are made to last. Our materials are carefully sourced and tested to ensure they meet our strict standards.

3.Competitive Price. We offer competitive pricie on all of our products without sacrificing quality and make the products competitive in your market.

4.Customization. We understand that every customer is unique, which is why we offer customized solutions tailored to their specific requirements. Whether it’s a custom shape or size, we can work with customers to create the ideal product for their application.

5.Safety. We take safety seriously and ensure that all of our products meet safety standards. Safty packing, prompt delivery time, and excellent after-sales services.

6.Large stocks. With a large stock of products on hand, we can better serve our customers, save money, and gain a competitive edge in their industry.

7. Overall solutions. We offer optimal and comprehensive solutions to supply the necessary refractory material for your high temperature kiln.

8.Long-term relationships. We believe in building long-term relationships with our customers based on trust and mutual benefit. We are committed to providing ongoing support and service to ensure customer satisfaction. Rongsheng Refractory can be used in many fields of steel, nonferrous metals, glass, cement, ceramic, petrochemical, machinery, boiler, light, and power industries. What’s more, Industrial distributors, refractory contractors, sales agents, trading companies, and refractory consultants can all benefit from promoting and selling our top-of-the-line refractory products. With a focus on durability, longevity, and performance, our products are designed to exceed your expectations and provide your customers with the best possible results.

So choosing us is the right choice for you.If you are interested in our products or if you have any question, pls feel free to contact us at any time. We will reply as soon as possible.