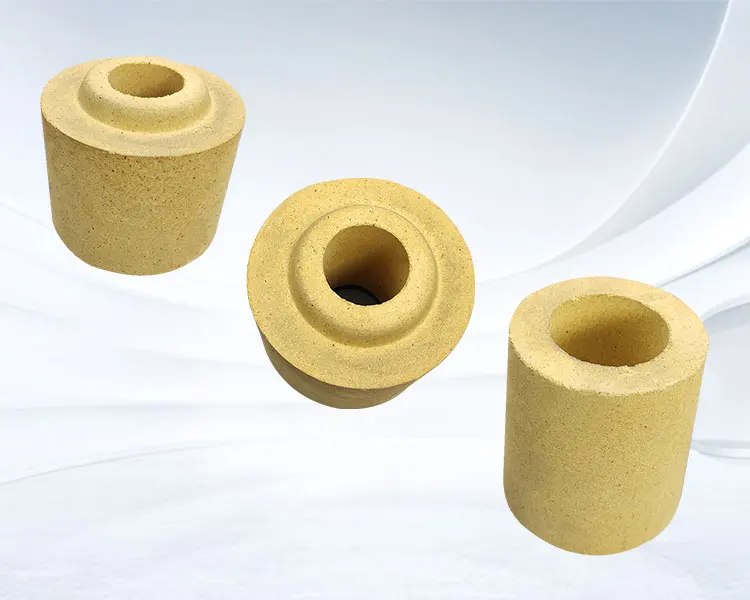

Flow Steel Brick / Steel Track brick / Alumina Runner Brick Description

Flow steel brick is a kind of flow steel brick used in the foundry industry. It is widely used in flat cast steel of various steel types (including stainless steel and various alloy steels). Hollow refractory brick for ingot mould. Ladle lining bricks, curved lining bricks, fired and non-fired plug bricks, sprue bricks, seat bricks and sleeve bricks made of cast steel in the ladle. The products have high refractoriness, good crack resistance and strong erosion resistance. The appearance is regular, the flow path is smooth, the size and variety are complete.

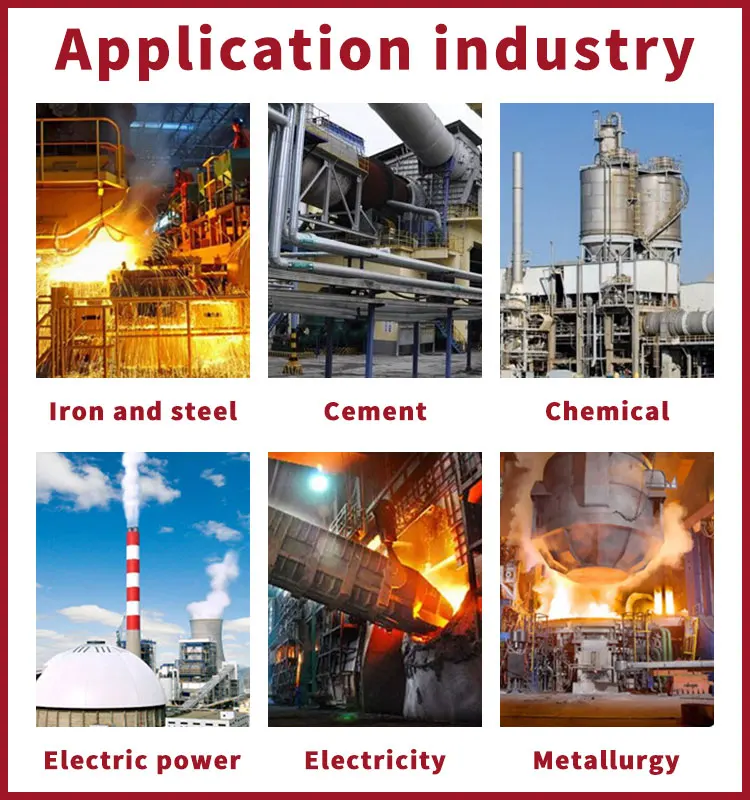

High Alumina Runner Bricks Applications

1. Steel furnaces; 2. Iron making furnaces; 3. Glass kiln; 4. Ceramic tunnel kiln; 5. Cement kiln;

Advantages of Flow steel brick:

1 High temperature and durable; 2 Good thermal shock resistance; 3 Good wear resistance and corrosion resistance; 4 Good thermal shock and peeling resistance; 5 higher mechanical strength;

6 Good volume stability at high temperature; 7.60% high alumina content

Product Specifications

|

Modle/item

|

Fire-clay

|

High Alumina

|

andalusite

|

||||

|

FC-36

|

FC-40

|

HL-48

|

HL-55

|

HL-65

|

HL-70

|

||

|

Al2O3 %

|

>36

|

>40

|

>48

|

>55

|

>65

|

>70

|

>57

|

|

Fe2O3 %

|

<2.0

|

<1.8

|

<2.0

|

<2.0

|

<2.0

|

<1.5

|

<2.0

|

|

Alkalinity %

|

<1.8

|

<1.8

|

<1.8

|

<1.8

|

<1.8

|

<1.8

|

/

|

|

Apparent porosity %

|

17-25

|

<22

|

<25

|

<26

|

<26

|

<25

|

<25

|

|

Bulk Density g/cm3

|

>2.1

|

>2.18

|

>2.2

|

>2.25

|

>2.3

|

>2.35

|

>2.30

|

|

Refractoriness ℃

|

>1700

|

>1710

|

>1750

|

>1770

|

>1790

|

>1790

|

>1790

|

About Rongsheng Refractory Factory

As professional refractory material supplier and manufacturer, Rongsheng Refractory Factory is located in Xinmi city, the “Capital of Refractory” in China. We specialize in refractory products for nearly 15 years, covering a full range of shaped and unshaped refractory products, such as High Alumina Series Bricks, Mullite Bricks, Corundum Series Bricks, Silica Series Bricks, Andalusite Bricks, Magnesia Series Brick, Carborundum Brick, Insulating Series Brick, Insulating and Dense Castables, also other related products for more sophisticated applications.

Company Profile

Henan Rongsheng Xinwei New Materials Research Institute Co., Ltd. is located in Henan, China. Our company has professional scientific and technical personnel and production team, and we have our own fully automated factories. For more than ten years, we have focused on the development and innovation of refractory materials and high-temperature furnace technology, and strive to provide customers with comprehensive, personalized and cost-effective services with high-quality products. Our products are widely used in electric power, metallurgy, petrochemical and other fields, and are exported to more than 70 countries and regions in the world such as Europe, America, Oceania, Southeast Asia, and the Middle East.

Henan Rongsheng Xinwei New Materials Research Institute Co., Ltd. is a first-class supplier of refractory materials, we can provide you with the most advantageous quotations and products. Looking forward to be your partner!

Our Certificates

Packing and Delivery