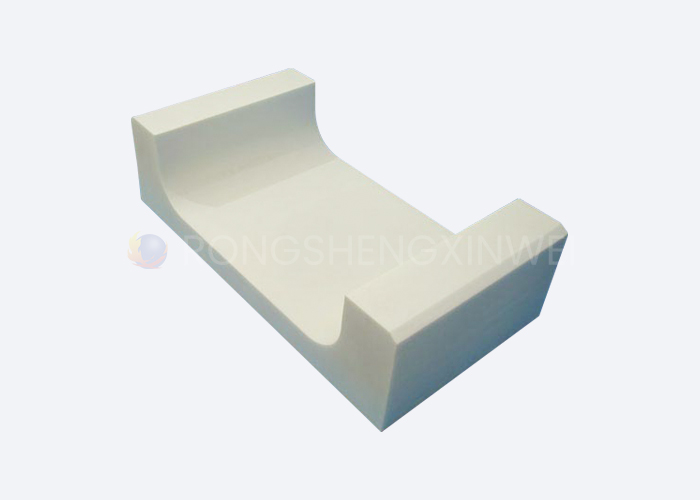

Description of Fused Corundum Bricks:

Fused α-corundum brick is mainly composed of α-Al2O3, which has high temperature resistance, strong alkali resistance, compact structure, excellent chemical stability, strong wear resistance, and is far more resistant to various slags than other aluminum silicates. It is an ideal material for metallurgical electrolytic cells and sliding rail bricks for heating furnaces.

Fused β-corundum bricks are mainly composed of β- Al2O3, with dense structure and strong spalling resistance, especially showing extremely high corrosion resistance to strong alkali vapor, no pollution to molten glass, and are used for upper structures with less glass raw materials scattered.

Fused α-β corundum brick is composed of about 50% of α- Al2O3 and β- Al2O3. The two crystals interlace to form a dense structure, which has excellent alkali resistance, and the corrosion resistance of molten glass is comparable to that of AZS bricks and does not pollute the glass liquid. , Mainly used for high-grade glass furnace working pool wall and pavement, forehearth and passage, etc.

Technical Parameter of Fused Corundum Bricks:

| Item | Index | ||

| Fused α-corundum Brick | Fused β-corundum Bricks | Fused α-β Corundum Brick | |

| Al2O3 % | 98 | 92 | 94.0 |

| Na2O % | 1.0 | 6.5 | 4.0 |

| SiO2+CaO+Fe2O3+TiO2 % | ≤1.0 | ≤1.5 | ≤2.0 |

| α-Corundum % | 90 | 2 | 44 |

| β-Corundum % | 4 | 97 | 55 |

| Glass Phase % | 6 | 1 | 1 |

| Bulk Density (Dense part) g/cm3 | 3.3 | 3.1 | 3.3 |

| Cold Crushing Strength MPa | 200 | 50 | 200 |

| 0.2Mpa Refractoriness Under Load ℃ | 1700 | 1700 | / |

| Static Resistance To Liquid Glass Erosion Depth mm/24h Ordinary Soda Lime Glass 1350℃×48h | / | / | 0.3 |

Why choose us?

1.Abundant Experience. Rongsheng Group have over 20 years experience in the refractory industry and we have a deep understanding of the materials and applications we work with. We can provide expert advice and guidance to help customers find the best solutions for their needs.

2.Quality products. We pride ourselves on providing high-quality refractory products that are made to last. Our materials are carefully sourced and tested to ensure they meet our strict standards.

3.Competitive Price. We offer competitive pricie on all of our products without sacrificing quality and make the products competitive in your market.

4.Customization. We understand that every customer is unique, which is why we offer customized solutions tailored to their specific requirements. Whether it’s a custom shape or size, we can work with customers to create the ideal product for their application.

5.Safety. We take safety seriously and ensure that all of our products meet safety standards. Safty packing, prompt delivery time, and excellent after-sales services.

6.Large stocks. With a large stock of products on hand, we can better serve our customers, save money, and gain a competitive edge in their industry.

7. Overall solutions. We offer optimal and comprehensive solutions to supply the necessary refractory material for your high temperature kiln.

8.Long-term relationships. We believe in building long-term relationships with our customers based on trust and mutual benefit. We are committed to providing ongoing support and service to ensure customer satisfaction. Rongsheng Refractory can be used in many fields of steel, nonferrous metals, glass, cement, ceramic, petrochemical, machinery, boiler, light, and power industries. What’s more, Industrial distributors, refractory contractors, sales agents, trading companies, and refractory consultants can all benefit from promoting and selling our top-of-the-line refractory products. With a focus on durability, longevity, and performance, our products are designed to exceed your expectations and provide your customers with the best possible results.

So choosing us is the right choice for you.If you are interested in our products or if you have any question, pls feel free to contact us at any time. We will reply as soon as possible.