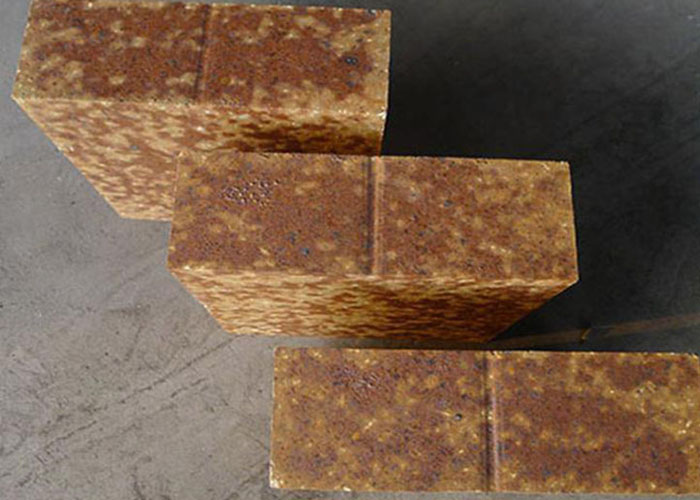

Product Overview of Wear-Resistant Silica-Mullite Brick High Temperature Compressive Strength Furnace Refractory Brick

Silica-mullite brick is crafted using sintered bauxite and high-density silicon carbide (SiC) through a process of pressing and high-temperature firing.

These bricks stand out for their excellent thermal shock resistance, superior wear resistance, and strong spalling resistance, making them an ideal choice for cement kilns. They are commonly used in the transition zone, cooling zone, and kiln outlet.

If you’re looking for a reliable supplier of silica mullite bricks at competitive prices from China, Rongsheng Refractory is here to assist you. Feel free to reach out to us for a free quotation!

Characteristics of Superior Quality Silica Mullite Bricks

High Strength: Designed to endure high-pressure operations.

Superior Wear Resistance: Performs well in abrasive conditions.

Outstanding Thermal Shock Resistance: Maintains stability during rapid temperature changes.

Extended Service Life: Ensures a prolonged operational lifespan.

Applications of Wear-Resistant Silica-Mullite Brick High Temperature Compressive Strength Furnace Refractory Brick

High-quality silica-mullite bricks are considered the top refractory material for large cement kilns, particularly in the:

Transition zone

Calcining zone

Cooling zone

Product Specification of Superior Quality Silica Mullite Bricks

| Item | RS-AZM1650 | RS-AZM1680 |

| Sic + SiO2 | ≥ 30 | ≥ 32 |

| Al2O3 | ≥ 65 | ≥ 65 |

| Refractoriness Under Load | ≥ 1650 | ≥ 1680 |

| Apparent Porosity (%) | ≤ 19 | ≤ 19 |

| Thermal Shock Resistance | ≥ 15 | ≥ 20 |

| Bulk Density (g/cm3) | ≥ 2.65 | ≥ 2.70 |

| Cold Crushing Strength (Mpa) | ≥ 90 | ≥ 100 |